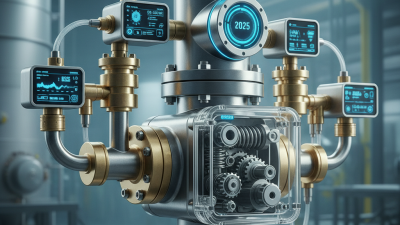

In today's industrial landscape, maintaining system efficiency is paramount, particularly in processes involving vacuum systems. A critical component in ensuring optimal performance is the vacuum relief valve, which plays a vital role in protecting equipment and enhancing operational reliability. According to a report by the American Society of Mechanical Engineers (ASME), improperly managed vacuum conditions can lead to serious operational failures, increasing maintenance costs by as much as 30%. This emphasizes the necessity of incorporating a vacuum relief valve in various applications, from chemical processing to food packaging, where fluctuations in pressure can adversely affect product quality and system integrity.

The vacuum relief valve functions as a safeguard, preventing excessive vacuum pressures that could cause structural damage to tanks and other vessels. As industry standards call for greater efficiency and safety, the integration of vacuum relief valves is becoming increasingly crucial. The Fluid Control Systems Report indicated that systems equipped with appropriate vacuum relief mechanisms experience up to a 40% reduction in failure rates, highlighting the importance of this seemingly small yet impactful component. Implementing a vacuum relief valve not only enhances safety but also aligns with the modern industry's focus on sustainability and cost-effectiveness, ultimately contributing to improved system efficiency and longevity.

Vacuum relief valves play a crucial role in maintaining the efficiency of various systems, particularly in applications relating to storage tanks, pipelines, and other enclosed environments. These valves act to prevent the formation of a vacuum that can lead to structural damage, reduced efficiency, and even catastrophic failures. When liquids are removed from a container, the pressure inside can drop significantly. A vacuum relief valve allows air to enter, equalizing the pressure and protecting the integrity of the system.

When installing or maintaining vacuum relief valves, it is important to consider their placement and calibration. Ensure that the valve is located at the highest point to effectively manage pressure changes throughout the system. Regularly check the valves for debris or wear, as any obstruction can hinder their performance. Understanding the specifications of your system can also aid in selecting the appropriate valve size and type.

Tips: Always consult with a professional when determining your system requirements, as they can offer valuable insights regarding the mandatory pressure settings and compliance with safety standards. Additionally, consider implementing routine inspections of your vacuum relief system to catch potential issues early, thereby enhancing overall efficiency and safety in your operations.

Maintaining proper pressure within a system is critical for ensuring operational efficiency and longevity. A vacuum relief valve plays a pivotal role in achieving this stability, allowing for the controlled intake of air or gas to mitigate negative pressure anomalies. According to the American Society of Mechanical Engineers (ASME), systems that maintain optimal pressure levels can enhance efficiency by up to 30%. This substantial improvement underscores the importance of pressure management in the overall design and function of industrial systems.

Moreover, improper pressure can lead to system failures or reduced performance, with the potential for costly downtime. A study by the International Journal of Mechanical Engineering indicates that systems that incorporate vacuum relief valves experience up to 25% fewer operational interruptions due to vacuum-related issues. These disruptions often stem from the inability to counteract pressure fluctuations, leading to material fatigue or equipment damage. Therefore, implementing a vacuum relief valve not only safeguards the infrastructure but also promotes a steady workflow, ultimately resulting in increased productivity and cost savings over time.

| Dimension | Details |

|---|---|

| Type of Valve | Vacuum Relief Valve |

| Function | Maintains balanced pressure within the system |

| Common Applications | Storage tanks, piping systems, vacuum processes |

| Consequences of Failure | System collapse, equipment damage, loss of efficiency |

| Maintenance Frequency | Quarterly inspections recommended |

| Typical Materials Used | Stainless steel, brass, PVC |

| Key Benefits | Improved safety, increased efficiency, reduced downtime |

Vacuum relief valves play a critical role in enhancing system efficiency and performance by maintaining optimal pressure levels within various industrial applications. By allowing controlled airflow into a vacuum system, these valves prevent the formation of harmful vacuum conditions that can lead to structural damage, equipment failure, or reduced performance. This regulation helps maintain the integrity of the system and supports smooth operational flow, which is essential for maximizing productivity and minimizing downtime.

Tips for ensuring the effective operation of vacuum relief valves include regular inspections and maintenance. Routine checks can help identify any blockages or wear that may compromise performance, thus prolonging the lifespan of the valve and the system. Additionally, ensuring correct sizing and installation is imperative; a vacuum relief valve that is improperly sized can result in inefficient pressure management, ultimately affecting overall system efficiency.

Another advantage of vacuum relief valves is their ability to enhance safety protocols in industrial settings. By preventing excessive vacuum levels, these valves mitigate risks associated with container collapse and product contamination. Implementing regular training for personnel on the importance and functionality of vacuum relief valves can further optimize system performance and ensure adherence to safety standards.

Vacuum relief valves are critical components in various industries, ensuring the efficient and safe operation of systems by preventing negative pressure that can lead to equipment failure. These valves find applications in sectors such as chemical processing, food and beverage, pharmaceuticals, and HVAC systems. In the chemical processing industry alone, the global market for vacuum relief valves is projected to grow from $800 million in 2022 to over $1 billion by 2026, reflecting an increase in demand for effective pressure management solutions.

In the food and beverage industry, vacuum relief valves play a crucial role in maintaining product quality and safety. For instance, during the packaging of liquids, these valves help prevent the collapse of containers caused by sudden pressure changes. According to a report by the Food Processing Suppliers Association, approximately 70% of manufacturers now emphasize the importance of vacuum relief systems in their operations, highlighting advancements in technology that enhance system integrity and efficiency.

Additionally, the pharmaceutical sector heavily relies on vacuum relief valves to ensure sterile processing environments. A 2023 study indicated that proper vacuum management can reduce contamination risks by up to 30%, underscoring the vital importance of these valves in maintaining product efficacy and safety standards.

Overall, the application of vacuum relief valves is broad and essential across multiple industries. The integration of these valves not only enhances system performance but also aligns with safety regulations and operational efficiency goals, making them indispensable in a variety of industrial settings.

When selecting a vacuum relief valve, it is crucial to consider several best practices that can enhance your system's efficiency. A vacuum relief valve is essential for preventing negative pressures that can lead to structural damage or operational inefficiencies. According to the American Society of Mechanical Engineers (ASME), improper pressure management is responsible for approximately 10% of draft failures in industrial applications. Choosing a valve with the correct pressure rating, material compatibility, and flow characteristics can significantly mitigate these risks. Conducting a thorough analysis of your system’s pressure requirements and environmental conditions is vital to ensure optimal functionality.

Maintenance of vacuum relief valves is equally important to ensure their reliability and effectiveness. Regular inspections should be carried out to check for wear and tear or blockages that could impede performance. A study by the National Institute of Standards and Technology (NIST) highlights that routine maintenance can improve valve longevity by up to 30%, which translates to cost savings and minimized downtime for operations. Implementing a maintenance schedule based on operational demands and manufacturer recommendations will provide a proactive approach to valve care, ensuring that your system remains efficient and effective over time.