In the rapidly evolving landscape of industrial applications, optimizing performance is crucial for maintaining a competitive edge. A recent industry report highlights that companies implementing advanced hose and fittings solutions can achieve up to 30% higher operational efficiency. This increase is largely attributed to the superior flexibility, durability, and reliability of modern hoses and fittings compared to traditional alternatives. According to the Fluid Power Association, nearly 80% of unplanned downtime in manufacturing is related to fluid leaks or hose failures, underscoring the importance of investing in quality hose and fittings. By leveraging innovative materials and designs, industries can not only enhance their productivity but also reduce maintenance costs and extend equipment lifespan.

As we delve into this topic, we will explore how hose and fittings are pivotal in unlocking efficiency across various industrial applications, driving performance to new heights.

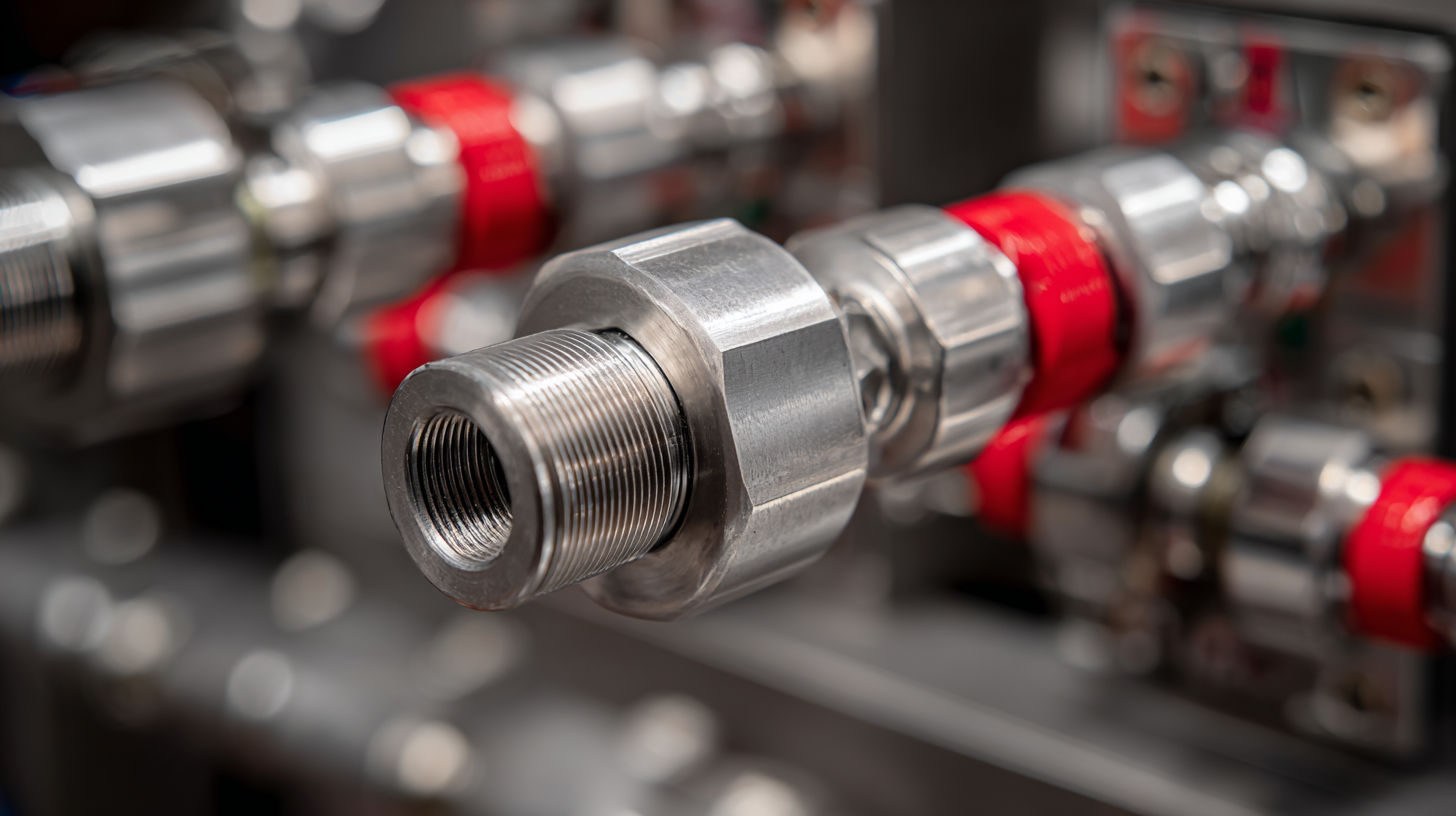

In industrial applications, the efficiency and performance of operations often hinge on the selection of the right hose and fittings. These components are not just simple connectors; they play a critical role in ensuring fluid transfer systems operate seamlessly, which can lead to a remarkable increase in operational performance, potentially enhancing it by 30%. The right hose can withstand pressures and temperatures specific to the task, while fittings ensure leak-free connections, minimizing downtime due to repairs or replacements.

In industrial applications, the efficiency and performance of operations often hinge on the selection of the right hose and fittings. These components are not just simple connectors; they play a critical role in ensuring fluid transfer systems operate seamlessly, which can lead to a remarkable increase in operational performance, potentially enhancing it by 30%. The right hose can withstand pressures and temperatures specific to the task, while fittings ensure leak-free connections, minimizing downtime due to repairs or replacements.

Tips: When selecting hoses and fittings, always consider the specific requirements of your application. Look for hoses that offer flexibility, durability, and chemical resistance to match the materials they will carry. Additionally, choose fittings that are compatible with the hose diameter and pressure ratings to prevent any risk of failure.

Furthermore, periodic maintenance and inspections of hoses and fittings can significantly prolong their lifespan and maintain efficiency. Regularly check for signs of wear and tear, and ensure connections remain tight and secure. This proactive approach not only keeps operations running smoothly but also contributes to overall safety in the workplace.

Efficient hose and fitting systems are key drivers of performance improvements across various industrial applications. With a projected growth rate of 9.7%, the hoses market is expected to reach USD 28.25 billion by 2032, highlighting the increasing demand for high-performance solutions in multiple sectors. These systems not only enhance operational efficiency but also contribute significantly to reducing downtime and maintenance costs, making them vital investments for industries looking to optimize production.

Efficient hose and fitting systems are key drivers of performance improvements across various industrial applications. With a projected growth rate of 9.7%, the hoses market is expected to reach USD 28.25 billion by 2032, highlighting the increasing demand for high-performance solutions in multiple sectors. These systems not only enhance operational efficiency but also contribute significantly to reducing downtime and maintenance costs, making them vital investments for industries looking to optimize production.

When setting up efficient systems, it's essential to choose hoses and fittings designed for durability and reliability. For instance, in hydraulic applications, advanced fittings can maintain higher pressure ratings while offering superior resistance to wear and leakage. This translates to more robust performance, especially in high-demand environments like mining and manufacturing.

Tips: Always inspect hoses regularly for signs of wear or damage to prevent unexpected failures. Additionally, consider the specific requirements of your application—such as temperature and pressure—when selecting hose materials to ensure optimal performance and longevity. Proper installation practices can further enhance the efficiency of your hose and fitting systems, leading to an overall increase in operational productivity.

Recent advancements in hose and fitting technology have transformed the landscape of industrial applications, delivering optimal efficiency and performance enhancements. According to a report by the Institute for Industrial Productivity, improved hose and fitting systems can lead to a notable 30% increase in operational efficiency. These innovations encompass a variety of materials and designs that reduce friction loss, enhance pressure management, and minimize leaks, thus significantly improving system reliability and productivity.

Tips for maximizing the benefits of new hose and fitting technologies include regularly inspecting and maintaining your systems to ensure optimal performance. Utilizing high-quality materials tailored to your specific application needs is also critical; for instance, reinforced hoses can withstand higher pressures and temperatures, extending service life. Additionally, training personnel on proper installation techniques can prevent common issues, further enhancing efficiency.

As industries continue to embrace these technological innovations, they not only experience enhanced performance but also significant cost savings. By implementing advanced hose and fitting solutions, companies can stay competitive and responsive to the demands of modern applications, effectively driving their productivity and success forward.

| Application Area | Performance Increase (%) | Innovation Type | Material Used | Temperature Rating (°C) |

|---|---|---|---|---|

| Hydraulic Systems | 35% | Reinforced Hoses | Synthetic Rubber | -40 to 100 |

| Food Processing | 30% | Sanitary Fittings | Stainless Steel | -20 to 90 |

| Chemical Transport | 40% | Corrosion-Resistant Hoses | Polypropylene | -10 to 80 |

| Construction Equipment | 25% | Heavy-Duty Fittings | Hybrid Polymeric Materials | -30 to 120 |

| Marine Applications | 33% | Flexible Hoses | Nylon | -20 to 70 |

In the realm of industrial applications, the choice of hoses and fittings plays a pivotal role in operational efficiency. Recent studies indicate that businesses utilizing high-quality hose and fitting solutions can experience performance improvements of up to 30%. For instance, a case study conducted by the Industrial Hose Manufacturer’s Association showed that a leading manufacturing company improved its fluid transfer efficiency by 35% after upgrading to advanced fittings and hoses designed to withstand higher pressures and temperatures. This upgrade not only minimized downtime but also reduced maintenance costs significantly, showcasing the tangible benefits of investing in superior components.

Another illuminating example comes from the oil and gas sector, where the reliability of hoses and fittings is critical. A report by the American Petroleum Institute highlighted that companies that implemented state-of-the-art hose assemblies reported a 20% decrease in leaks and failures, contributing to safer operations and substantial cost savings. These real-world impacts underscore the importance of selecting the right hose and fitting solutions—demonstrating not just improvements in efficiency, but also in safety and overall operational reliability.

In the pursuit of unlocking efficiency in industrial applications, the selection and maintenance of hoses and fittings play a crucial role. According to the Hydraulic Institute, improper hose and fitting choices can lead to a 25-30% reduction in performance. This statistic highlights the importance of choosing the right materials, dimensions, and connections to optimize fluid transfer and minimize downtime. Adopting best practices in the selection process can exponentially increase operational efficiency and longevity of equipment.

Tips for selecting the right hoses and fittings include evaluating the fluid type, temperature, and pressure requirements. For instance, using a hose designed for higher pressure ratings than the system requires can provide a safety margin, thereby increasing reliability. Regular inspections and maintenance are also vital; replacing worn-out fittings and hoses at the first sign of wear can prevent leaks and catastrophic failures, as studies show that maintaining a structured preventive maintenance program can decrease downtime by up to 40%.

Moreover, training staff on best practices in handling and installing hoses and fittings can lead to significant improvements in operational safety and efficiency. Engaging with manufacturer guidelines and industry standards will ensure that your equipment is not only compliant but also optimized for performance. Prioritizing these best practices will ultimately drive 30% higher performance across various industrial applications.