In the realm of fluid transfer, efficiency and reliability are paramount, and camlock fittings emerge as crucial components that enhance these aspects significantly. Designed for quick connection and disconnection, camlock fittings offer a practical solution for various industries, including agriculture, construction, and chemical processing. Their versatility allows for seamless integration with hoses and pipes, facilitating a smoother flow of liquids and gases while minimizing the risk of leaks or spills. As we delve into the benefits of camlock fittings, we will explore their various types, applications, and the reasons why they are a preferred choice for professionals seeking to optimize fluid transfer systems. This ultimate guide aims to unlock the potential of camlock fittings, equipping you with the knowledge to make informed decisions for your fluid management needs.

Camlock fittings play a crucial role in the efficient transfer of fluids across various industries, including agriculture, chemical processing, and construction. These fittings allow for quick and secure connections, reducing the time and labor involved in fluid handling. According to a report by MarketsandMarkets, the global fittings market is expected to grow significantly, driven largely by the increasing demand for effective fluid transfer systems. Camlock fittings contribute to this demand by providing a reliable connection that minimizes leakage and ensures safety during operations.

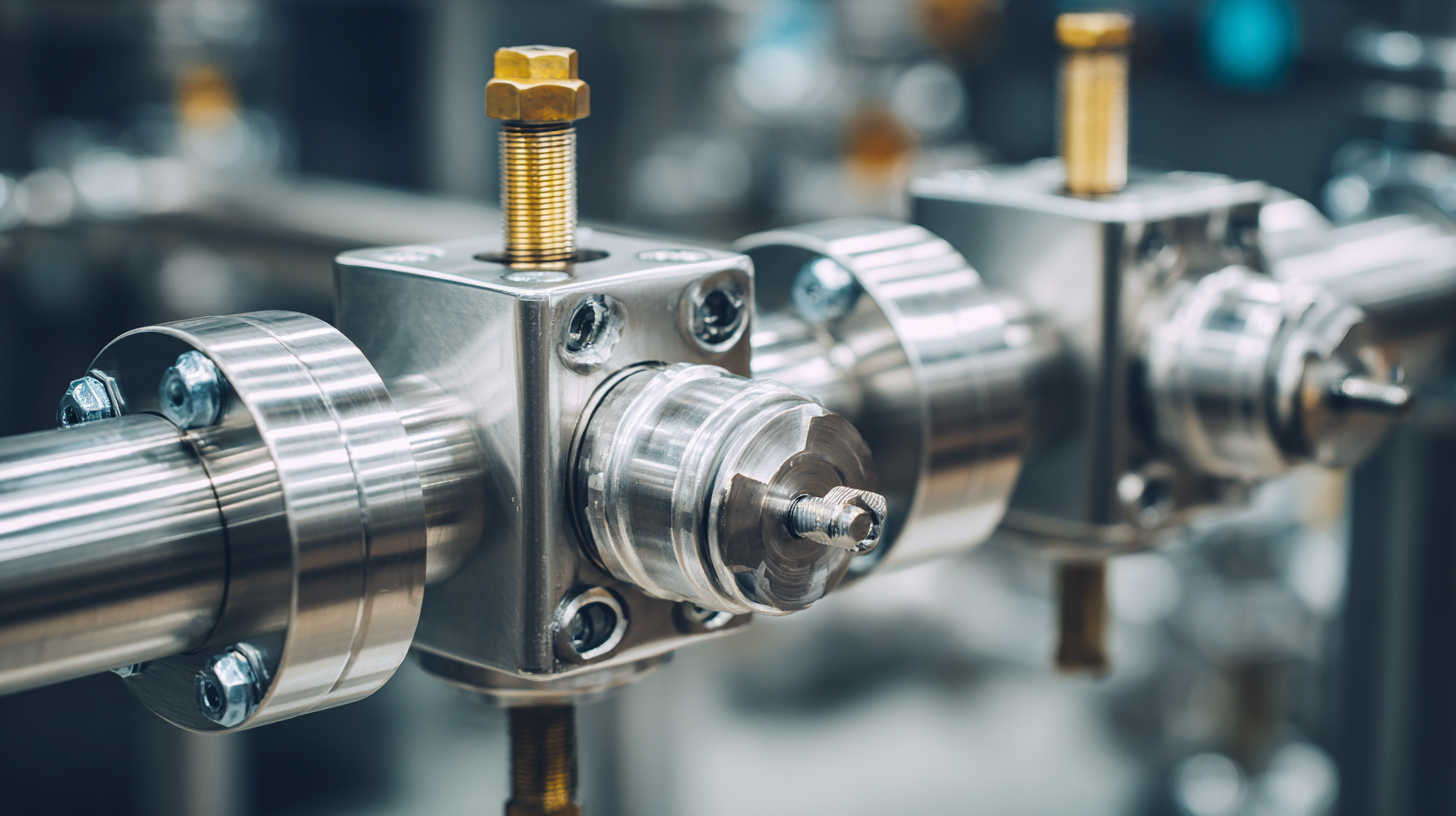

The essential functionality of camlock fittings lies in their design, which promotes easy use and versatility. Available in various materials such as aluminum, stainless steel, and plastic, camlock fittings cater to a wide range of fluids, from water to hazardous chemicals. A study published by the American Society of Mechanical Engineers (ASME) revealed that utilizing camlock fittings can enhance the overall efficiency of fluid transfer systems by up to 30%. This efficiency is vital in high-stakes environments where precise fluid control is paramount, making camlock fittings an indispensable component in modern fluid management strategies.

When evaluating fluid transfer methods, camlock fittings stand out against traditional couplings due to their unique design and ease of use. According to a report by the Fluid Power Journal, nearly 60% of industries prefer camlock fittings for applications requiring rapid connect and disconnect capabilities. This is largely attributed to their simple lever-lock mechanism, which allows for a secure connection while minimizing the time and labor typically associated with traditional threaded fittings.

Camlock fittings are revolutionizing fluid transfer across various industries due to their efficiency, durability, and ease of use. According to a report by MarketsandMarkets, the global camlock fittings market is expected to reach USD 1.7 billion by 2027, demonstrating a robust CAGR of 5.6% from 2022. This growth is largely attributed to the increasing demand for lightweight and reliable connections in sectors such as agriculture, chemicals, and oil and gas.

In the agriculture industry, camlock fittings are essential for quick coupling and decoupling of hoses used in irrigation and chemical distribution. A study by the Agricultural Equipment Technology Conference highlights that 65% of farmers prefer camlock systems for their time-saving benefits and leak-proof performance, leading to enhanced operational efficiency. Similarly, in the chemical sector, the ability to safely transfer hazardous fluids makes camlock fittings the preferred choice among safety-conscious professionals. The Chemical Processing Magazine reports that equipment downtime due to connection failures can cost facilities up to $20,000 per incident, underscoring the critical role of reliable fittings in these high-stakes environments.

When selecting the right camlock fittings for your fluid transfer needs, several key considerations come into play. First and foremost, ensure that the material of the camlock fitting is compatible with the fluid you are transferring. Common materials include aluminum, stainless steel, and plastic, each with its own advantages based on the nature of the fluid. For example, stainless steel is ideal for corrosive substances, while aluminum is lightweight and suited for less abrasive applications.

**Tip:** Always check the temperature and pressure ratings of the fitting to guarantee safe and efficient operation. This will help prevent leaks or failures that could occur if the fitting is not rated for your specific conditions.

Another critical factor is the size of the fittings. Camlock fittings come in various sizes, and choosing the correct diameter is essential for optimal flow rates. A fitting that is too small may create a bottleneck, while one that is too large can lead to unnecessary fluid loss.

**Tip:** When measuring for size, consider the entire system, including hoses and connections, to ensure compatibility throughout your fluid transfer setup. This attention to detail will not only enhance performance but also extend the lifespan of your equipment.

To ensure the longevity of camlock fittings, regular maintenance is crucial. According to the Fluid Power Journal, proper cleaning and inspection are essential practices that should be conducted at least once every quarter. Dirt and debris can accumulate in the fittings, leading to corrosion and failure. Utilizing a soft brush and non-abrasive cleaning agents can effectively remove contaminants without damaging the fittings' surfaces. Moreover, maintaining an appropriate seal is vital; seals should be inspected for wear and replaced when any signs of deterioration are visible. This simple practice can prevent leaks and prolong the operational lifespan of the fittings.

Another significant aspect of camlock fitting maintenance is the importance of proper storage. According to a report from the Hose and Coupling Association, improper storage can reduce the lifespan of fittings by up to 40%. It is advisable to store fittings in a dry, climate-controlled environment, away from direct sunlight and extreme temperatures. Utilizing protective cases or racks can also help prevent physical damage. By adhering to these maintenance tips, users can maximize the efficiency and longevity of their camlock fittings, ensuring a reliable fluid transfer system in various applications.