In industrial systems, the potential for pressure-related incidents looms large, making the role of the safety valve critical for ensuring operational integrity and safety. According to a report by the , nearly 50% of industrial accidents can be attributed to pressure failures, highlighting the necessity for effective safety mechanisms. Safety valves serve as essential components that protect equipment and personnel by automatically releasing excess pressure, thus averting catastrophic failures. The National Board of Boiler and Pressure Vessel Inspectors indicates that proper sizing and maintenance of safety valves can reduce the risk of system failure by up to 80%. With the complexity of modern systems and the rising demand for efficiency, understanding how safety valves function and their best practices is more crucial than ever for engineers and operators alike. This guide aims to provide insights and practical tips on maximizing the reliability of safety valves in diverse applications.

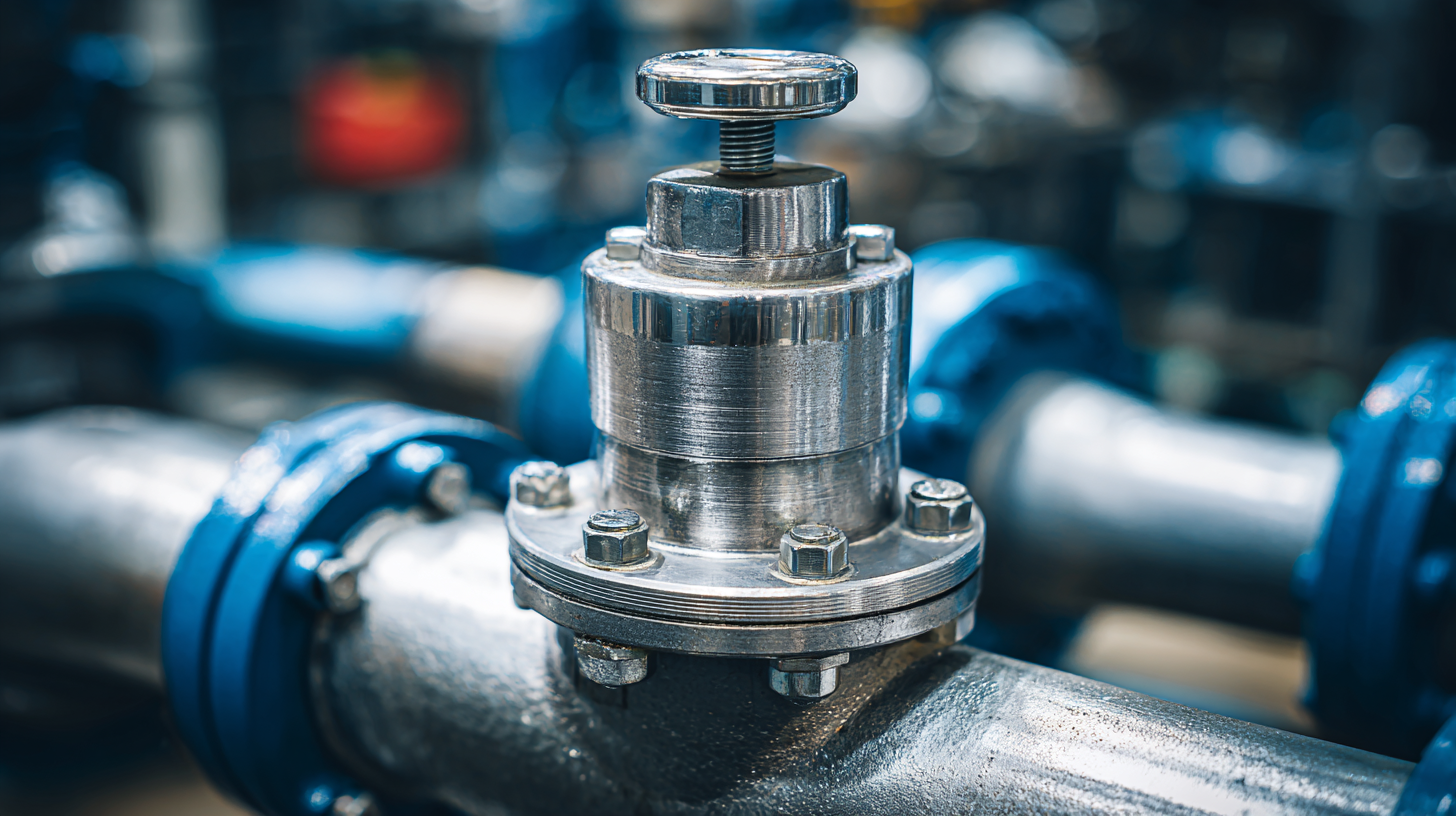

Safety valves play a crucial role in protecting pressure systems by ensuring that excess pressure is safely relieved before reaching dangerous levels. These mechanical devices are engineered to open automatically when the pressure within a system exceeds a predetermined threshold, effectively preventing catastrophic failures. When a system experiences a rise in pressure, the safety valve reacts by venting the excess gas or liquid, thereby maintaining equilibrium and safeguarding equipment and personnel.

The functionality of safety valves is rooted in their design, which typically includes a spring-loaded mechanism that remains sealed under normal operating conditions. When the pressure rises, it overcomes the spring force, allowing the valve to open and release pressure. Once the pressure drops back to a safe level, the valve reseals to maintain system integrity. This automatic operation is essential in various industries, such as oil and gas, chemical processing, and power generation, where maintaining optimal pressure levels is critical for safety and efficiency. Overall, safety valves are vital components that enhance the reliability of pressure systems while preventing potential hazards.

When selecting safety valves for your systems, several key factors must be considered to ensure optimal performance and protection against pressure risks. First and foremost, it is essential to understand the specific application and operating conditions where the safety valve will be utilized. Factors such as temperature, pressure range, and the type of fluid can greatly influence the best valve choice.

Tips: Always review the manufacturer's specifications for compatibility with your system’s media and operating environment to prevent any potential failures.

Another critical aspect is the sizing of the safety valve. An improperly sized valve can lead to insufficient protection or frequent nuisance tripping, which can disrupt operations. Engineers should conduct a thorough analysis using the appropriate calculations to determine the correct valve size based on flow requirements and relief scenarios.

Tips: Utilize software tools or consult with experienced professionals for accurate sizing calculations to enhance the reliability of your pressure safety systems.

Safety valves are crucial components in protecting systems from pressure risks, ensuring that excess pressure doesn’t lead to catastrophic failures. Installing safety valves correctly is essential for their effectiveness and reliability. According to industry reports, improper installation accounts for approximately 30% of safety valve failures. This statistic underscores the need for a precise, step-by-step installation guide to minimize risks and maximize safety.

To install a safety valve, begin by selecting the appropriate valve based on your system’s specifications, including pressure ratings and the type of fluid involved. Ensure that the installation location is accessible for future inspections and maintenance. Follow the manufacturer’s guidelines meticulously, ensuring proper orientation and securing the valve firmly to prevent leakage. This methodical approach not only ensures optimal performance but also complies with regulatory standards that mandate safety measures for pressure systems.

Furthermore, regular testing and maintenance of safety valves are critical. Reports indicate that about 20% of valves are never tested after installation, exposing systems to potential failures. Scheduling routine checks can help identify any issues early, maintaining the integrity of the safety system and protecting against pressure-related incidents. Adopting these best practices is vital for any operation that relies heavily on pressure equipment.

This chart shows the reported incidents of various pressure risks in industrial systems. Understanding these risks helps in the proper installation and maintenance of safety valves, ensuring system integrity and safety.

Safety valves are critical components in various systems, designed to protect against excessive pressure that could lead to catastrophic failures. To ensure these valves function optimally, regular maintenance is essential. Neglecting safety valve upkeep can result in malfunction, potentially allowing pressure to reach dangerous levels.

**Tip 1:** Schedule periodic inspections to assess the condition and functionality of safety valves. Look for signs of wear, corrosion, or buildup that could impede their operation. These inspections should be part of a comprehensive maintenance plan.

**Tip 2:** Regularly test the valves to ensure they open at the designated pressure. This can help identify any issues before they lead to system failures. Testing should mimic actual operating conditions to provide an accurate assessment of the valve's performance.

By integrating these maintenance practices, you can enhance the reliability of safety valves, ensuring they protect your systems effectively from pressure risks. Regular attention not only prolongs the life of the valves but also contributes to the overall safety and efficiency of your operations.

Safety valves play a crucial role in protecting systems from pressure risks, but they can encounter various issues that may compromise their effectiveness. Common problems include leakages due to wear and tear, improper seating, and excessive corrosion. According to a report by the American Society of Mechanical Engineers (ASME), approximately 20% of safety valve failures can be attributed to poor maintenance practices. Regular inspections and timely replacements are essential to ensure these critical components function correctly and prevent potential hazards.

When troubleshooting safety valve issues, it is important to follow systematic techniques. Start by visually inspecting the valve for signs of wear or damage. If a valve is leaking, checking the sealing surfaces for proper alignment is crucial. A recent study indicated that nearly 30% of safety valve failures result from improper installation, emphasizing the need for adherence to manufacturer guidelines.

**Tips:**

- Implement a routine maintenance schedule based on operational hours to catch issues early.

- Utilize pressure testing to confirm the sitting and sealing capabilities of your safety valves regularly.

- Consider using advanced monitoring systems that alert you to performance irregularities before they escalate into significant problems.

| Safety Valve Type | Common Issues | Troubleshooting Techniques | Maintenance Frequency |

|---|---|---|---|

| Spring-loaded Safety Valve | Leakage, Misalignment | Inspect seating surfaces, Adjust spring tension | Every 6 months |

| Pilot-operated Safety Valve | Failure to open, blocked vent | Check pilot control signals, Clean vents | Annually |

| Balanced Safety Valve | Chattering, Incorrect set pressure | Adjust set pressure, Inspect travel | Every 3 months |

| Electric Safety Valve | Electrical failure, Valve sticking | Test electrical connections, Exercise valve manually | Monthly |