When it comes to selecting the right suction hose for your needs, expert insights and practical considerations can make all the difference. John Smith, a renowned expert in the suction hose industry, emphasizes, "Choosing the right suction hose is not merely about finding one that fits; it’s about understanding your specific application and ensuring optimal functionality." With various materials, sizes, and specifications available, it becomes crucial to navigate the complexities of selecting a suction hose that aligns with both efficiency and safety standards.

This ultimate guide aims to provide you with ten essential tips that will simplify the decision-making process and empower you to make an informed choice. Whether you are working in industrial settings, agricultural applications, or construction sites, understanding the unique characteristics and capabilities of suction hoses will ensure they meet your demanding requirements. From assessing the compatibility of materials to recognizing the importance of diameter and length, mastering these elements will enhance your workflow and contribute to successful outcomes.

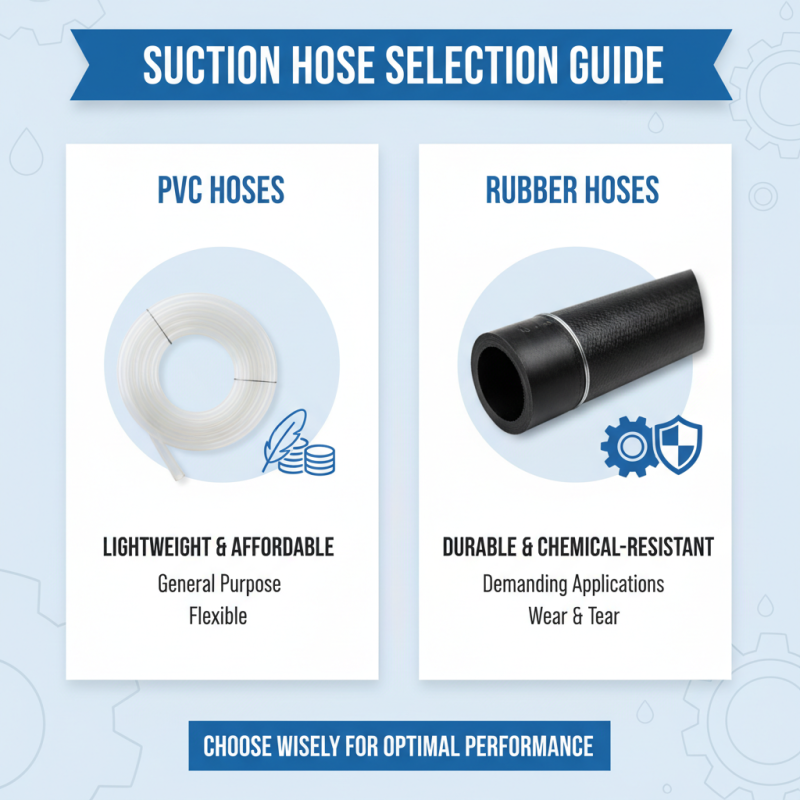

When selecting the right suction hose, several key factors must be considered to ensure optimal performance and reliability. One of the primary considerations is the hose’s material. Different materials offer varying levels of flexibility, durability, and resistance to chemicals. For instance, hoses made from PVC are lightweight and affordable, while rubber hoses provide superior resistance to wear and tear, making them ideal for more demanding applications. Evaluating the intended use will help determine the most suitable material for your needs.

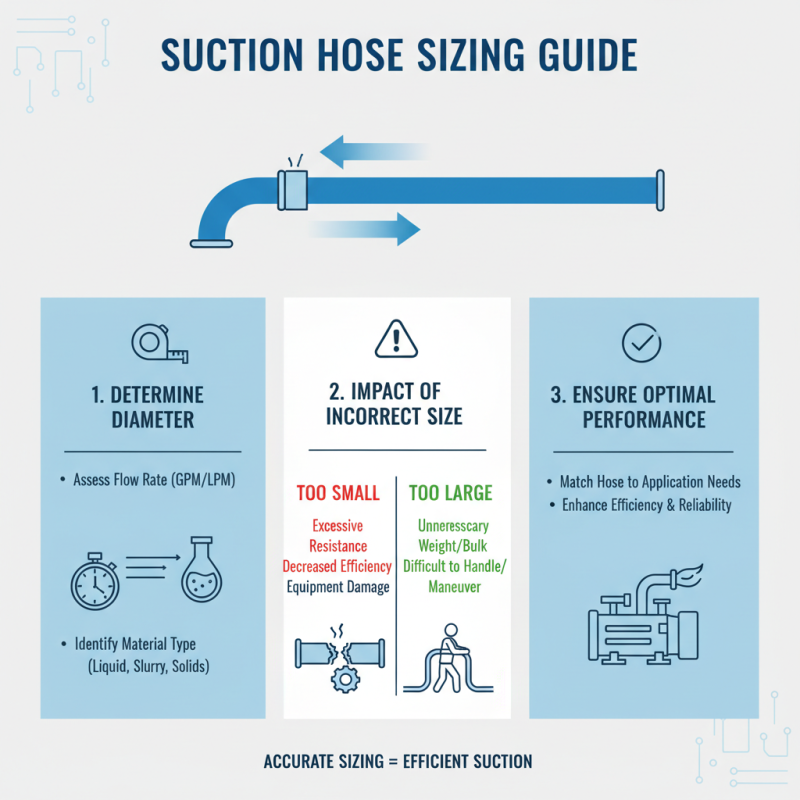

Another vital aspect is the hose's diameter and length. The diameter affects the flow rate, while the length can impact suction efficiency. A larger diameter allows for greater volume transfer, but it may be bulkier and harder to handle. Similarly, a longer hose can decrease suction power due to friction loss, particularly in low-pressure applications. It is crucial to strike a balance that aligns with the specific requirements of your equipment and the materials being moved. Considering these factors will guide you in making an informed decision when choosing a suction hose.

When selecting a suction hose, understanding the different types available and their specific uses is crucial for ensuring optimal performance in various applications. Suction hoses come in multiple materials, including PVC, rubber, and polyurethane, each suited for different environments. For instance, PVC hoses are lightweight and ideal for transferring water and light chemicals, while rubber hoses excel in high-temperature and high-pressure scenarios. According to a report by Grand View Research, the global industrial hoses market is projected to reach $18.78 billion by 2026, highlighting the increasing reliance on versatile suction hoses across industries.

One essential tip when choosing a suction hose is to assess the material compatibility with the fluids being transferred. For example, certain chemicals can degrade PVC, making rubber or specialized thermoplastic options more suitable. Additionally, consider the hose's rigidity; a more flexible hose can navigate tight spaces better, yet might not be suitable for high-vacuum usages. Always verify manufacturer specifications against your operational requirements to ensure safety and efficiency.

Another crucial aspect is the hose diameter, which affects both flow rate and suction power. A larger diameter can accommodate higher volumes, but can also lead to a decrease in suction strength if not properly matched to the pump being used. As indicated by the latest industry standards, optimal diameter selection is key to achieving enhanced performance in fluid transfer applications. Make sure to review these considerations thoroughly before making your final decision.

When choosing the right suction hose, the material is a crucial factor that directly impacts performance, durability, and efficiency. There are several common materials available, each with unique properties suitable for different applications. For example, PVC hoses offer flexibility and resistance to weather and chemicals, making them a popular choice for light-duty tasks. On the other hand, rubber hoses provide superior abrasion resistance and can handle higher temperatures, making them ideal for heavier applications.

Tip: Consider the environment in which the hose will be used. If you anticipate exposure to harsh chemicals or extreme temperatures, choose a hose material that is specifically designed for those conditions.

Additionally, polyurethane hoses are gaining popularity due to their lightweight feel and excellent resistance to cuts and punctures. They are particularly effective in applications where flexibility and bend radius are critical. Also, keep in mind that some materials may require specific fittings, so always check compatibility when selecting your suction hose.

Tip: Evaluate the weight and flexibility requirements for your tasks. If mobility and ease of handling are essential, opt for lighter materials that still meet your performance needs.

When it comes to selecting a suction hose, accurate sizing is paramount to ensure efficient performance and reliability. The first step in measuring your suction hose needs is to determine the diameter required for your specific application. This involves assessing the flow rate and the type of materials being moved. A hose that is too small can create excessive resistance, leading to decreased efficiency and potential damage to your equipment. Conversely, an oversized hose may result in unnecessary weight and bulk, making it difficult to handle and maneuver.

In addition to the diameter, the length of the suction hose is another critical factor. It's essential to measure the distance from the suction point to the discharge point accurately. A longer hose may require consideration of additional factors such as bends and elevation changes that could impact suction efficiency. Taking into account these variables will ensure that you choose a hose that minimizes pressure loss and optimizes flow, ultimately enhancing your operational effectiveness. Proper sizing will not only improve the performance but also extend the lifespan of your suction equipment, making it a vital consideration in your selection process.

When selecting a suction hose, maintaining its longevity is critical to ensuring efficiency and performance. Proper maintenance not only prolongs the life of the hose but also enhances safety during operations. According to industry reports, regular inspections and cleaning schedules can increase the lifespan of suction hoses by up to 30%. This statistic underscores the importance of treating hoses with care and vigilance.

Routine checks for wear and tear, including checking for abrasions, cracks, or any signs of fatigue, are essential. Operators should also ensure that hoses are not subjected to extreme temperatures or harsh chemicals unless specified by manufacturer guidelines. The American National Standards Institute (ANSI) recommends that suction hoses be stored in a clean, dry area away from direct sunlight to prevent degradation from UV exposure.

Moreover, using the correct fittings and ensuring they are securely attached can prevent leaks, which not only protects the hose from damage but also enhances the overall efficiency of the system.

Another critical aspect of maintenance involves the cleansing procedure post-operation. Flushing hoses with water or recommended cleaning solutions can help remove any residual materials that may cause blockages or internal wear. A study by the Hose Manufacturers Association notes that unclean hoses can lead to a reduction in suction efficiency by as much as 25%, emphasizing the need for diligent cleaning practices. By adhering to these maintenance tips, users can maximize the performance and durability of their suction hoses, leading to safer and more effective operational procedures.