In the realm of industrial safety, pressure relief valves play a pivotal role in safeguarding equipment and personnel from overpressure scenarios. According to the 2021 Global Pressure Relief Valve Market Report, the industry is projected to grow at a compound annual growth rate (CAGR) of 5.3%, reflecting the increasing importance of pressure management in various sectors including oil and gas, chemical processing, and pharmaceuticals. As systems become more complex, the demand for advanced pressure relief valve technologies is surging, emphasizing the need for optimal performance and reliability.

As we look ahead to 2025, the top digital pressure relief valves are set to revolutionize safety protocols through enhanced precision and real-time monitoring capabilities. Studies indicate that integrated digital solutions can reduce the likelihood of failure by up to 40%, making them indispensable in maintaining system integrity. The integration of IoT technology into pressure relief valves not only improves responsiveness but also facilitates predictive maintenance, thereby optimizing operational efficiency and safety standards across industries. This article explores the best types of pressure relief valves, highlighting innovative designs that prioritize performance and reliability in high-stakes environments.

In 2025, the landscape of pressure relief valve technology is set to witness significant innovations that prioritize safety and efficiency. Digital innovations are leading the charge, integrating advanced sensors and IoT capabilities into pressure relief valves. These smart devices allow for real-time monitoring and data analysis, enabling operators to anticipate issues before they escalate into safety hazards. The use of machine learning algorithms further enhances the ability to predict pressure fluctuations and optimize valve performance, ensuring maximum reliability in critical applications.

Tips for selecting the right pressure relief valve include considering the specific needs of your system. Always assess the compatibility of your existing infrastructure with new digital technologies. It’s essential to look for valves that offer remote monitoring features, as these can significantly reduce manual inspection time and improve response rates. Regularly updating your technology and staying informed about the latest advancements can enhance overall system safety.

Furthermore, training staff on how to utilize these digital tools effectively plays a crucial role in maintaining optimal safety standards. Ensure that your team understands the functionalities of any new equipment and can interpret the data generated by smart pressure relief valves accurately. This proactive approach will not only bolster safety but also promote a culture of continuous improvement in your operations.

When selecting safety pressure relief valves, several key factors significantly influence the decision-making process. First and foremost, the application environment plays a crucial role. Each industrial setting has its own specific requirements in terms of temperature, pressure range, and the nature of the fluids or gases involved. Understanding these parameters ensures that the chosen valve can withstand operational demands and avoid premature failure.

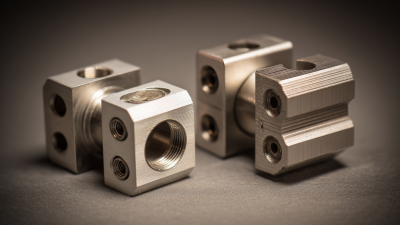

Another critical factor is the valve’s set pressure and flow capacity. Proper sizing of the valve is essential to ensure it can effectively relieve excess pressure without being oversized, which could lead to inefficiencies and increased wear. Additionally, compliance with industry standards and certification requirements cannot be overlooked, as they guarantee that safety and performance benchmarks are met.

Lastly, maintenance requirements and the availability of replacement parts are vital considerations, as they impact the long-term reliability and operational efficiency of the pressure relief system. These factors collectively aid in the selection of the most suitable safety pressure relief valve tailored to specific operational needs.

The integration of digital monitoring technologies in pressure relief valves represents a significant advancement in ensuring optimal safety and performance. Digital monitoring systems gather real-time data on the valve's operating conditions, enabling operators to make informed decisions and promptly address any anomalies. According to a report by MarketsandMarkets, the global digital valve positioner market is projected to reach $1.7 billion by 2025, underscoring the growing importance of digital solutions in valve management.

Furthermore, digital monitoring enhances the predictive maintenance capabilities of pressure relief valves. With accurate data analytics, organizations can identify wear and tear patterns before they escalate into critical failures. Research published in the Journal of Pressure Relief Systems indicates that regular digital monitoring can increase the reliability of pressure relief valves by up to 30%, leading to decreased downtime and maintenance costs. This proactive approach not only upholds safety standards but also improves operational efficiency across various industries, including oil and gas, chemical processing, and pharmaceuticals.

| Valve Type | Digital Monitoring Feature | Operation Pressure (psi) | Material | Applications |

|---|---|---|---|---|

| Spring-Loaded | Real-time pressure monitoring | 15 to 3000 | Stainless Steel | Oil and Gas |

| Pilot-Operated | Automated flow measurement | 50 to 5000 | Brass | Chemical Processing |

| Thermal Relief | Temperature and pressure alerts | 100 to 1500 | Carbon Steel | Water Systems |

| Electronic Control | Digital display of pressure data | 20 to 4000 | Alloy | Pharmaceuticals |

In the ever-evolving field of industrial safety, the emergence of digital pressure relief valves represents a significant advancement in managing pressure levels in various applications. A comparative analysis of the top digital models of 2025 reveals key differences in features, performance, and reliability. These valves utilize sophisticated sensors and digital control systems, allowing for real-time monitoring and adjustments, which significantly enhances safety measures in high-pressure environments.

When evaluating the leading digital pressure relief valve models, performance metrics such as response time, accuracy, and durability come into sharp focus. Some models are equipped with advanced algorithms that optimize valve response based on the fluctuations in pressure, ensuring that systems operate within designated safety parameters. Additionally, ease of integration with existing control systems and the capability for remote monitoring have become crucial deciding factors for industries seeking to upgrade their safety protocols. The effectiveness of these models ultimately hinges on their ability to provide consistent, reliable relief in a wide array of pressure scenarios while minimizing the risks associated with pressure buildups.

Maintaining optimal functionality in digital pressure relief valves is essential for ensuring safety and efficiency in various industrial applications. One of the best practices is to implement a rigorous regular inspection schedule. This involves not only visual assessments but also using diagnostic tools to monitor the valve’s performance metrics. Early detection of wear or malfunction can prevent costly failures and enhance the overall reliability of the system.

Another critical aspect is ensuring proper calibration of the digital valves. Regular recalibration based on manufacturer specifications helps maintain precision in pressure settings. Operators should be trained on the importance of understanding the operational environment, as factors such as temperature and fluid viscosity can impact valve performance. Additionally, keeping the software updated is essential, as manufacturers often release new updates that enhance functionality and security, ensuring the valve operates as intended under varying conditions.