When it comes to selecting the right tri clamp size for your specific applications, it is crucial to consider various factors that can significantly impact your setup's efficiency and effectiveness. Tri clamps, or tri clover fittings, are widely used in industries such as brewing, food processing, and pharmaceuticals for their ability to create hygienic and secure connections between pipes and equipment. Choosing the correct size ensures optimal flow rates, minimizes leaks, and enhances the overall safety of your operation.

In this guide, we will provide you with essential tips for selecting the appropriate tri clamp size tailored to your needs. You will learn about key measurements, compatibility with different tubing, and how to assess the requirements of your system. By understanding these critical aspects, you can make informed decisions that will lead to better performance and reliability in your processes. Whether you are setting up a new system or upgrading existing connections, this article will equip you with the knowledge necessary to navigate the various options available and find a tri clamp that meets your specifications efficiently.

Tri clamps, also known as tri-clover fittings, are essential components in various industries, particularly in food and beverage processing, pharmaceuticals, and brewing. Understanding the basics of tri clamps is crucial for anyone looking to ensure their equipment operates seamlessly. Tri clamps feature a circular disc and a rubber gasket that provide a secure connection, allowing for easy assembly and disassembly. This unique design helps maintain sanitized conditions during operations, making them ideal for applications where hygiene is paramount.

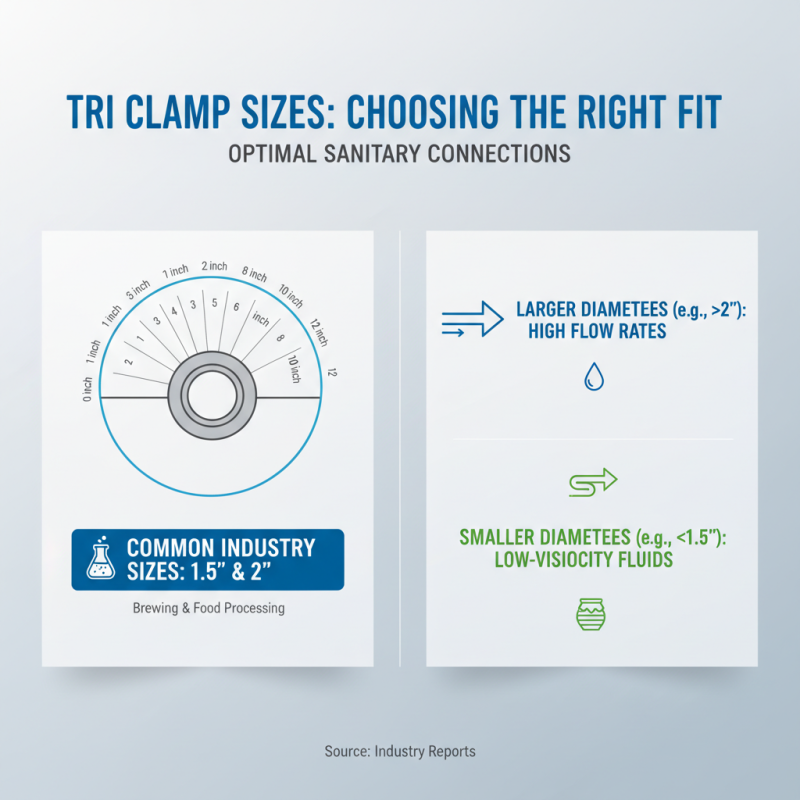

The size of a tri clamp directly influences its suitability for specific tasks. Common sizes range from 1 inch to 12 inches in diameter, catering to different flow rates and pressure requirements. Selecting the right size involves considering the pipe diameter and the volume of material being transported. Additionally, different applications might require unique fittings, such as reducing or expanding tri clamps, to ensure compatibility with existing piping systems. By understanding the basic principles behind tri clamps and their sizing, users can make informed decisions that optimize both performance and safety in their operations.

When selecting the appropriate tri clamp size, it is crucial to first identify your specific needs. The application for which you require the tri clamp significantly influences the size you should choose. For instance, consider the type of equipment or tubing you will be connecting—different systems may necessitate varying clamp sizes to ensure a secure fit and effective performance. Additionally, understanding the flow requirements of your system can determine whether a larger or smaller clamp is necessary to maintain optimal pressure and fluid dynamics.

Moreover, assessing the material and diameter of the piping involved is essential. Tri clamps come in a variety of sizes to accommodate different tubing dimensions, and choosing the right one is vital to prevent leaks or pressure loss. It is also wise to consider future scalability. If you anticipate expanding your system or adjusting your processes, opting for a versatile size can save you time and resources in the long run. By clearly defining your system's specifications and potential growth, you can make a more informed decision regarding the size of the tri clamp that will best meet your operational needs.

When it comes to selecting the right tri clamp size for your equipment, accurate measurements are crucial. The first step in measuring your existing equipment is to assess the diameter of the corresponding connection points. Use a caliper or tape measure to determine the outer diameter of the pipe or fitting. Be sure to measure at the widest point to ensure the most accurate reading. This measurement will be essential in identifying the appropriate tri clamp size that will secure the connection without any leaks.

In addition to measuring diameter, it’s important to consider the thickness of the material used in your setup. Different materials can affect the fit and sealing capabilities of the tri clamp. For instance, a thicker wall will require a different type of clamp or even a specific gasket to ensure a tight seal. Taking note of the flange or fitting style is another critical factor; standard tri clamps will have specific compatibility with particular types of tubing or hose connections. By diligently measuring your existing equipment and taking these factors into account, you can confidently choose the right tri clamp size that will meet your specific needs.

| Clamp Size (inches) | Pipe OD (inches) | Application | Common Uses |

|---|---|---|---|

| 1" | 1.315" | Small Scale Equipment | Homebrewing, Small Pumps |

| 1.5" | 1.900" | Medium Scale Processing | Brew Kettles, Storage Tanks |

| 2" | 2.375" | Large Scale Operations | Industrial Equipment, Food Processing |

| 2.5" | 2.875" | High Volume Systems | Chemical Processing, Large Tanks |

| 3" | 3.500" | Heavy Duty Applications | Waste Management, High Pressure Systems |

When selecting the right tri clamp size, it's essential to understand the range of available options and their specific features. Tri clamps, also known as sanitary fittings, come in various sizes, typically ranging from 0.5 inches to 12 inches in diameter. According to industry reports, the most commonly used sizes in commercial brewing and food processing applications are the 1.5-inch and 2-inch tri clamps, which provide a balance of strength and flexibility for a variety of connection setups. The choice of size can significantly impact the overall efficiency and sanitization process, as larger diameters facilitate higher flow rates, while smaller sizes may be sufficient for low-viscosity applications.

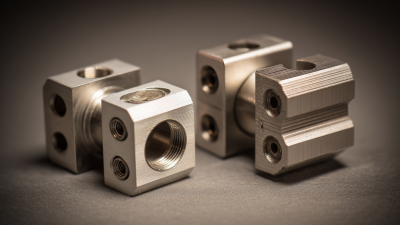

Moreover, the type of material used for tri clamps also plays a crucial role in their functionality and durability. Most tri clamps are manufactured from stainless steel, which offers resistance to corrosion and ease of cleaning, essential for maintaining hygienic conditions in food and beverage industries. Reports indicate that sanitary fittings crafted from 304 stainless steel are prevalent but are often found in industrial uses, while 316 stainless steel clamps offer increased resistance to more aggressive environments, including various chemical applications. Understanding the specific features and benefits of each size and material will enable users to make informed decisions tailored to their unique operational needs.

When selecting the right tri clamp size for your application, it’s crucial to avoid several common mistakes that can lead to inefficiency and costly mistakes. One of the most prevalent errors is misjudging the necessary tri clamp size due to a lack of understanding of flow dynamics within the system. According to a report from the Process Equipment Manufacturers Association (PEMA), improper sizing can result in flow restrictions or excessive turbulence, which may compromise product quality and increase maintenance costs by up to 30%.

Another common mistake is overlooking the importance of compatibility with existing equipment. Many professionals fail to consider the variations in flange designs or material composition when selecting tri clamps. The American Society of Mechanical Engineers (ASME) emphasizes that mismatches can lead to leaks and equipment failures. For instance, choosing a tri clamp that is not compatible with sanitary fittings can cause contamination and hinder compliance with industry regulations.

Finally, neglecting the impact of temperature and pressure ratings is another critical error. Research published by the International Society of Pharmaceutical Engineering (ISPE) highlights that many users select tri clamps based solely on size without accounting for the specific pressure and temperature conditions they will face. Failure to align these parameters could lead to catastrophic failures during operation. Understanding these pitfalls ensures a more efficient and robust system tailored to your specific needs.