In any industrial system, a pressure relief valve is crucial for safety and efficiency. John Smith, a leading expert in valve technology, once said, "A pressure relief valve is the last line of defense against catastrophic failure." These devices play a pivotal role in preventing excessive pressure buildup, which can lead to dangerous situations.

Imagine a steam boiler where pressure levels can soar unexpectedly. Without a functioning pressure relief valve, this situation could escalate quickly. Significant safety risks are inherent in neglecting this component. Pressure relief valves help maintain system integrity. They act not only as protectors but also as essential components in system design.

However, some users overlook the importance of regular maintenance. They might assume that once installed, a pressure relief valve will function indefinitely. This misconception can lead to dire consequences. Regular checks and balances are essential. Understanding the importance of these valves aids in preventing failures that can impact both personnel and operations.

Pressure relief valves play a vital role in many industrial systems. These devices prevent excessive pressure buildup, which can lead to catastrophic failures. According to the American Society of Mechanical Engineers (ASME), nearly 57% of industrial accidents are linked to uncontrolled pressure scenarios. This alarming statistic highlights the need for effective pressure management solutions.

In chemical processing plants, pressure relief valves are crucial. They help maintain safe operating pressures. The Occupational Safety and Health Administration (OSHA) reports that improper pressure control accounts for 31% of serious industrial accidents. By implementing reliable pressure relief systems, facilities can protect their workers and equipment. Many industrial facilities still overlook the proper sizing and placement of these valves, leading to potential risks.

Moreover, these valves are essential in the oil and gas sector. A report from the National Fire Protection Association (NFPA) indicates that equipment failure in these industries can lead to explosions. Regular maintenance and testing are often neglected, leading to inefficiency. Facilities should prioritize the evaluation of their pressure relief systems to safeguard operations.

Pressure relief valves play a crucial role in many systems. They help maintain safe pressure levels. These devices automatically release pressure when it exceeds a specified limit. This prevents potential explosions or equipment failure. The mechanism is simple yet effective. When pressure builds up, the valve opens, allowing excess fluid or gas to escape.

The components of a pressure relief valve include a spring and a disc. The spring is calibrated to a precise pressure point. When the pressure inside the system rises, it pushes against the disc, overcoming the spring force. As a result, the valve opens. Once the pressure drops below the set point, the valve closes again. This cycle is vital for the stability of the system.

However, not all systems are equipped with these safety valves. In some cases, manufacturers overlook them, leading to dangerous situations. Regular testing and maintenance are crucial to ensure these valves function properly. Understanding their mechanisms allows operators to appreciate their importance. Ignoring this could lead to catastrophic failures and costly repairs. Pressure relief valves are essential for a safe and efficient system.

Pressure relief valves (PRVs) are crucial for safety in various systems. They prevent overpressure, which can lead to catastrophic failures. When selecting a PRV, understanding the different types is essential for effective use.

There are several types of pressure relief valves. The most common include spring-loaded valves, pilot-operated valves, and rupture disks. Spring-loaded valves are simple and effective for many applications, managing low to medium pressure. According to the American Society of Mechanical Engineers (ASME), these valves have a failure rate of around 1 in 10,000. Pilot-operated valves provide better control for high-pressure scenarios. They are used in chemical processing and oil & gas industries for stability. Rupture disks, on the other hand, are used when immediate release is critical.

Tips: Regular maintenance is key. Inspect PRVs at least once a year. Look for signs of wear or corrosion. Addressing issues early can prevent equipment failure. Choose the right valve type for your specific needs. It’s not one-size-fits-all; consider your system’s requirements carefully.

Incorporating PRVs into your system can seem straightforward, yet miscalculations are common. Operators sometimes select valves based on guesswork. This can lead to inadequate pressure control. Collecting accurate data on system pressure fluctuations is vital for effective valve selection. Optimize your system by understanding pressure dynamics deeply; don’t rely solely on previous experiences.

| Valve Type | Function | Applications | Pressure Range |

|---|---|---|---|

| Spring Loaded | Automatically opens at a preset pressure to relieve excess pressure. | Pipelines, Boilers, and Pressure Vessels | Up to 3000 psi |

| Pilot Operated | Uses system pressure to open and close the valve. | Oil and Gas, Chemical Processing | Up to 5000 psi |

| Vacuum Relief Valve | Prevents vacuum conditions that can damage equipment. | Storage Tanks, Pipelines | N/A |

| In-line Relief Valve | Installed directly into the pipeline to alleviate excessive pressure. | Fluid Transfer Systems | Up to 2500 psi |

| Bursting Discs | A sacrificial membrane that ruptures at a specific pressure. | Chemical Storage, High-Pressure Systems | Up to 10000 psi |

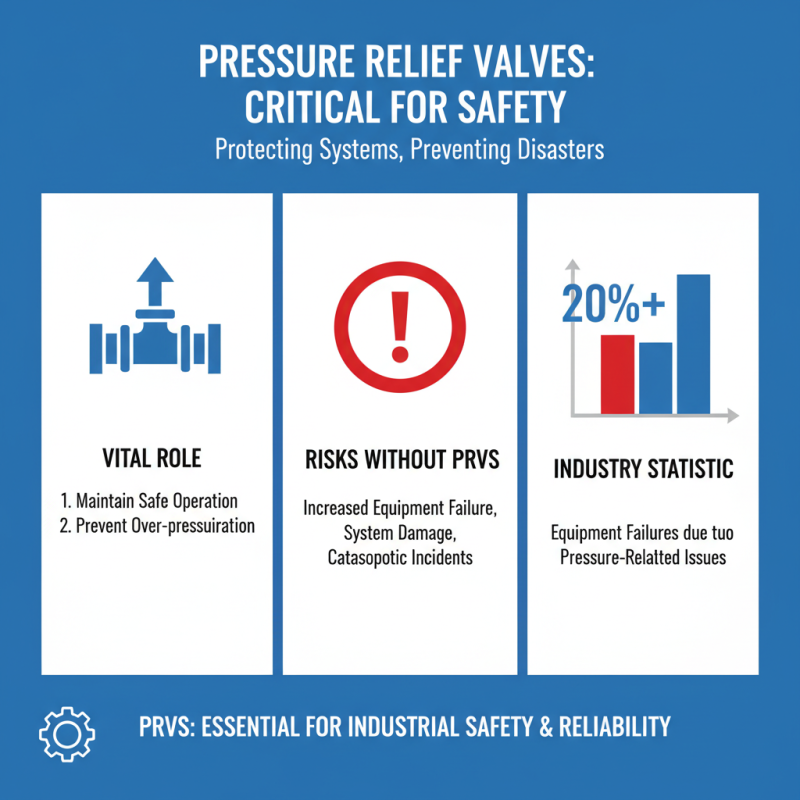

Pressure relief valves (PRVs) are critical for maintaining safe operation in various systems. Without them, the risks significantly increase. A recent industry report highlighted that over 20% of equipment failures in industrial settings stem from pressure-related issues. This statistic underscores the vital role of PRVs in preventing catastrophic incidents.

When pressure builds beyond safe limits, equipment can fail dramatically. Such failures often lead to leaks, explosions, or even injuries. According to the National Fire Protection Association, roughly 20% of industrial accidents are pressure-related. Many accidents could have been avoided with properly functioning pressure relief valves. Their absence places both personnel and equipment at significant risk.

Operators may underestimate the importance of these valves. Regular maintenance is often neglected. A lack of awareness regarding pressure management can lead to dire consequences. Safety inspections should prioritize PRVs, ensuring they function correctly. Reports indicate that equipment installed with PRVs has a 30% lower failure rate. This data illustrates how essential it is to incorporate pressure relief valves into any system.

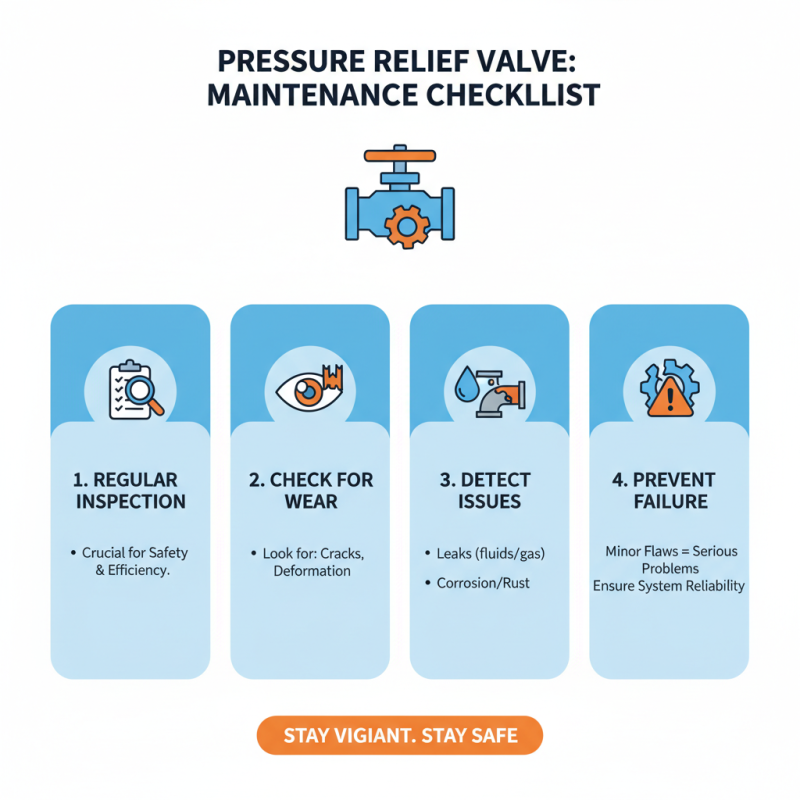

Maintaining a pressure relief valve is crucial for safety and efficiency. Regular inspection is key. Check for signs of wear. Look for leaks or corrosion. These issues can lead to failure. Even minor flaws can cause serious problems in a system.

Cleaning the valve regularly helps prevent build-up. Dirt and debris can affect performance. A simple wipe-down can make a difference. It's also wise to lubricate moving parts as recommended. This reduces friction and extends the valve’s life.

Keep an eye on the pressure readings. If they seem off, investigate. Anomalies may indicate underlying issues. Failure to address them could compromise the entire system. Regular training for staff on valve maintenance is essential. They should feel confident in identifying potential problems.