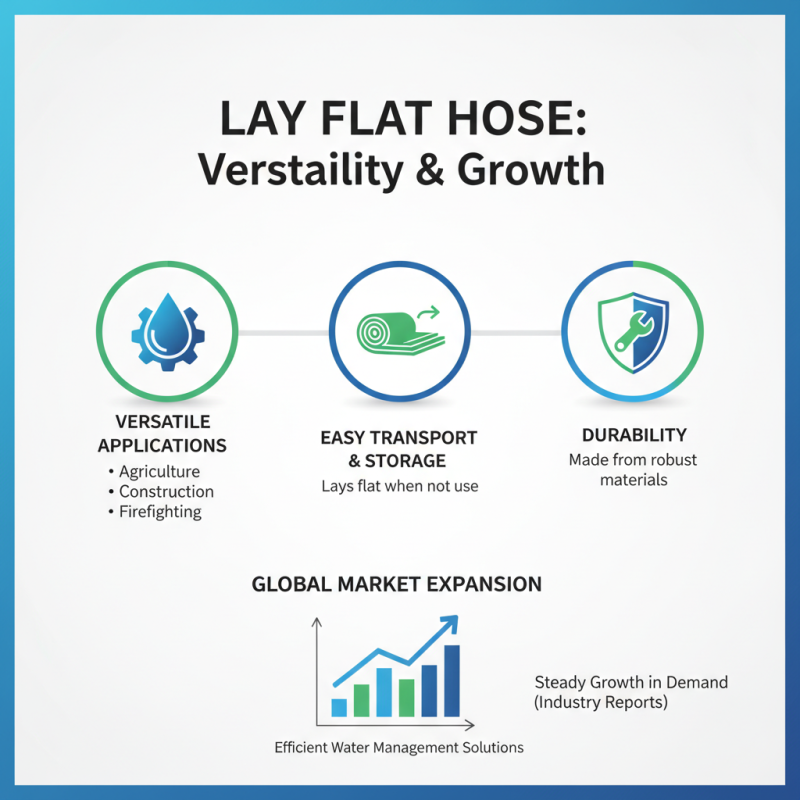

Lay flat hoses are increasingly vital in various industries, from agriculture to construction. According to industry reports, the global lay flat hose market was valued at approximately $2 billion in 2022. This figure indicates a growing reliance on flexible, adaptable solutions for water transport. Their design allows them to be stored compactly, making transportation simpler and more efficient.

In applications like irrigation, lay flat hoses deliver water effectively across fields. Their unique construction prevents kinking and damage during use. However, users must choose the right material and diameter for specific needs, which can complicate the buying process. Many reports suggest that improper selection leads to issues like reduced flow rates and premature wear.

Lay flat hoses possess both strengths and weaknesses. While they are lightweight and easy to handle, they may not withstand extreme pressure as well as rigid pipes. Understanding the proper use and limitations of lay flat hoses is crucial. This knowledge helps users optimize performance while minimizing costs and environmental impact. The increasing demand for eco-friendly options further emphasizes the need for efficient hoses in today’s market.

A lay flat hose is a versatile tool commonly used in various industries, including agriculture, construction, and firefighting. Its design allows it to lay flat when not in use, making it easy to transport and store. The hose is typically made from durable materials, which contributes to its longevity. According to recent industry reports, the global lay flat hose market has been expanding steadily, signaling increased demand for efficient water management solutions.

These hoses are often used for irrigation purposes. They can carry large volumes of water over considerable distances. For example, a well-designed lay flat hose can deliver water at a flow rate of up to 700 gallons per minute. This efficiency is crucial in regions facing drought or limited water resources. However, not all lay flat hoses are created equal. Certain types may not withstand high pressure or extreme temperatures, which can lead to performance issues.

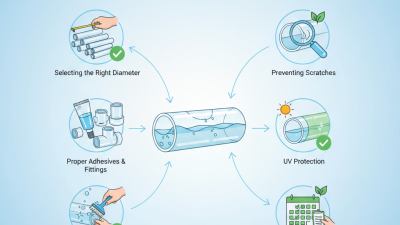

**Tip:** When selecting a lay flat hose, consider the intended application and local climate conditions. Check for specifications that match your needs.

Users should be aware of maintenance practices as well. Lay flat hoses need to be cleaned regularly to prevent clogs and reduce wear. Neglecting this can shorten their lifespan. It may seem tedious, but it is essential for consistent performance. A little effort in upkeep pays off in the long run.

Lay flat hoses are versatile tools used in various applications for water transportation. Their design allows them to lay flat when not in use, saving storage space. This feature makes them ideal for irrigation, construction, and firefighting, where space can be limited. Made from durable materials, they resist wear and tear, yet their lightweight structure ensures easy handling.

One key feature of lay flat hoses is their flexibility. They can easily bend around obstacles, adapting to different terrains. This adaptability is crucial in places where rigid hoses may not function well. Moreover, many lay flat hoses have reinforced edges, enhancing their durability. Some versions are resistant to kinks, allowing for uninterrupted water flow. However, users must be careful; improper handling can lead to leaks or damage.

Another important aspect is their easy connection to water sources. They can attach to standard fittings with little effort. This simplicity in setup enhances their usability. However, choosing the right length for your needs is vital. An excessively long hose might create pressure issues. Always consider your project’s requirements. The ability to lay flat seems perfect, yet it requires thoughtful usage to maximize benefits.

This chart illustrates the key features and typical applications of lay flat hoses based on their diameter and pressure ratings. As shown, larger diameter hoses are suitable for higher flow rates, while varying pressure ratings determine their suitability for different tasks.

Lay flat hoses are designed for various applications, from agricultural irrigation to industrial pumping. Their unique structure allows for easy storage and transportation. These hoses can expand when filled with water and flatten out when empty. This feature ensures efficient use of space, which is crucial in many settings.

The working mechanism of lay flat hoses relies on the materials used in their construction. Typically, they are made of PVC or polyurethane. According to industry reports, PVC hoses often have a burst pressure of around 300 PSI. This means they can handle significant pressure without failure. However, lower quality hoses may not meet this standard. Such discrepancies highlight the importance of selecting the right hose for specific tasks.

When using lay flat hoses, installation and maintenance are key. Proper connections prevent leaks and pressure loss. Data indicates that a 10% reduction in hose diameter can lead to a 20% decrease in flow rate. This shows the critical nature of size and fit. Regular inspections can identify wear and tear early, preventing costly downtime. Understanding these factors can lead to more effective use of lay flat hoses in various situations.

| Dimension | Description | Typical Uses |

|---|---|---|

| Material | Usually made from PVC or other synthetic materials | Agriculture, firefighting, construction |

| Size Range | Available in a variety of diameters, typically from 1 inch to 8 inches | Water transfer, dewatering |

| Operating Pressure | Typically rated for pressures between 50 to 150 PSI | Pumping applications, irrigation systems |

| Temperature Range | Can operate in temperatures from -20°C to 60°C (-4°F to 140°F) | Various industrial applications |

| Flexibility | Highly flexible and easy to maneuver | Quick deployment in emergency situations |

Lay flat hoses are versatile tools used across numerous industries. They are particularly favored for irrigation, mining, and construction. In agriculture, these hoses enable efficient water delivery to crops. Their flexibility makes them easy to store and transport. Farmers can quickly deploy them for irrigation purposes, reducing labor and time.

In construction, lay flat hoses are essential for dewatering processes. They transport water away from job sites effectively. This prevents flooding and keeps work areas safe. Their lightweight design allows for easy handling. Workers can maneuver them quickly, ensuring projects remain on schedule. However, improper handling can lead to leaks or bursts, requiring attention.

Emergency services also rely on lay flat hoses. They are vital for firefighting and flood control. Firefighters use them to supply water quickly. Flood response teams deploy them to redirect water flow. The rapid deployment is crucial in life-threatening situations. But they require regular inspections to ensure reliability. Without proper maintenance, their effectiveness can diminish.

Lay flat hoses are versatile tools, but they require care. Regular maintenance helps extend their life and keeps them functional. After each use, inspect the hose for any signs of wear. Look for cracks or kinks. These weak points can lead to leaks.

Cleaning is essential. Rinse the hose with water to remove debris. Storing it properly also matters. Avoid leaving it exposed to sunlight for long periods. UV rays can cause damage. Instead, coil the hose and store it in a cool, dry place.

Watch out for tangling. Hang the hose on a hook to prevent knots. A tangled hose may not lay flat, affecting its performance. Using it improperly can lead to unnecessary repairs. When in doubt, take a moment to assess the hose before use. Being proactive saves time and money.