When embarking on a project that requires a stainless pipe, making the right choice is crucial. Stainless pipes are widely used in various applications, from plumbing to industrial settings. Understanding the essential factors affecting your selection can save you time and resources.

Many people overlook the importance of pipe grades and finishes. These aspects significantly influence durability and performance. Choosing the wrong type can lead to future complications. Consider the environment where the pipe will be installed. Harsh conditions could necessitate a specific grade of stainless steel to prevent corrosion.

Additionally, dimensions play a vital role. A pipe that doesn't fit correctly can hinder workflow. It’s worth contemplating the long-term implications of your choice. A small oversight today can lead to bigger issues down the road, prompting a need for revisiting decisions. By considering these details, you can make an educated choice that aligns perfectly with your project's requirements.

When selecting stainless steel pipes, understanding the available types is crucial. Stainless steel pipes are primarily categorized based on their grades and finishes. Common grades include 304 and 316, each possessing unique properties. For example, 304 pipes are corrosion-resistant and widely used in various applications. On the other hand, 316 pipes offer better resistance to chlorides, making them suitable for marine environments.

Another consideration is the pipe finishes. You can find pipes in several finishes like polished, brushed, or raw. A polished finish often provides an aesthetically pleasing look. However, it may require more maintenance. Raw finishes, while functional, might show wear and tear over time. Pay attention to these details, as they affect both the performance and lifespan of the pipes.

Nonetheless, it’s common to overlook specific requirements during this selection process. Many projects require detailed specifications. Not all stainless steel pipes will fit seamlessly into every application. Research and understanding show how crucial it is to match the pipe’s properties with project needs. It would be beneficial to consult with experts or review performance metrics.

Selecting the right stainless pipe for your project requires careful consideration of several key factors. One critical aspect is the type of stainless steel used. For example, Type 304 is often recommended for its excellent corrosion resistance. According to the 2022 Stainless Steel Market Report, 304 stainless steel makes up about 60% of the industry’s demand. It is versatile and widely used in various applications, but it may not suit highly corrosive environments.

Pipe size is another essential factor. The diameter and wall thickness directly affect the pipe’s strength and flow efficiency. A study by the American Society of Mechanical Engineers (ASME) indicates that improper sizing can lead to a 20% drop in efficiency. An oversized pipe might not only waste material but can also lead to increased operational costs.

You also need to think about compliance with industry standards. Many projects require strict adherence to specific codes. Failing to meet these can lead to costly rework. You might find that cheaper options don’t always meet these regulations, leading to potential safety risks. Balancing cost, compliance, and material properties is vital. Every decision can lead to long-term consequences. Be sure to weigh your options carefully.

Choosing the right size of stainless pipe is crucial for any project. It affects both functionality and safety. To start, determine the fluid or gas flow requirements. This includes knowing the maximum flow rate and pressure. For example, a water system requires different sizing than one for gas.

Next, consider the dimensions of the project space. Measure the areas where the pipes will be installed. Often, there isn’t enough space for larger pipes. This can lead to issues later if adjustments are needed. Many overlook this detail, which can cascade into bigger problems. Smaller diameter pipes can increase flow resistance.

It's also essential to account for fittings and connections. These components can take up additional space. Sometimes, they might require a different size pipe than initially planned. This can complicate the layout. Always double-check measurements and make adjustments as necessary. Validate your choices to avoid unnecessary complications.

When selecting stainless pipes, understanding the significance of pipe thickness and schedule is crucial. Pipe thickness dictates strength and durability. The schedule refers to the pipe wall thickness relative to its diameter. For instance, Schedule 40 pipes offer a good balance for various applications. However, for more demanding projects, Schedule 80 pipes may be necessary. Reports indicate that thicker pipes can withstand higher pressures and temperatures, essential in industrial settings.

Tip: Always assess the specific requirements of your project. Review the environment and pressure levels. If corrosion resistance is a concern, consider the material composition carefully. A thicker pipe generally provides better durability but can be more expensive.

Keep in mind that not all projects require the same specifications. Some may suffer from using overly thick pipes, leading to increased costs without added benefits. Evaluate your system's needs and optimize accordingly. A thoughtful approach can streamline your procurement process.

| Tip Number | Tip Description | Importance of Thickness | Recommended Schedule |

|---|---|---|---|

| 1 | Determine the application requirements | Critical for pressure and flow | Schedule 40 |

| 2 | Consider environmental factors | Affects corrosion resistance | Schedule 10 |

| 3 | Evaluate the need for strength | Thickness enhances structural integrity | Schedule 80 |

| 4 | Check compatibility with fluids | Thickness aids in preventing leaks | Schedule 40 |

| 5 | Assess the installation method | Thicker pipes may require special tools | Schedule 10 or Schedule 40 |

| 6 | Review industry standards | Compliance is critical for safety | Schedule 80 |

| 7 | Calculate the cost versus lifespan | Thicker pipes can be cost-effective long-term | Schedule 40 or Schedule 80 |

| 8 | Seek expert advice when needed | Expert insights may highlight thickness needs | Depends on application |

| 9 | Check supplier reliability | Reliable suppliers ensure quality, including thickness | Schedule 40 |

| 10 | Test the material if possible | Testing confirms physical properties, including thickness | Any schedule as per testing |

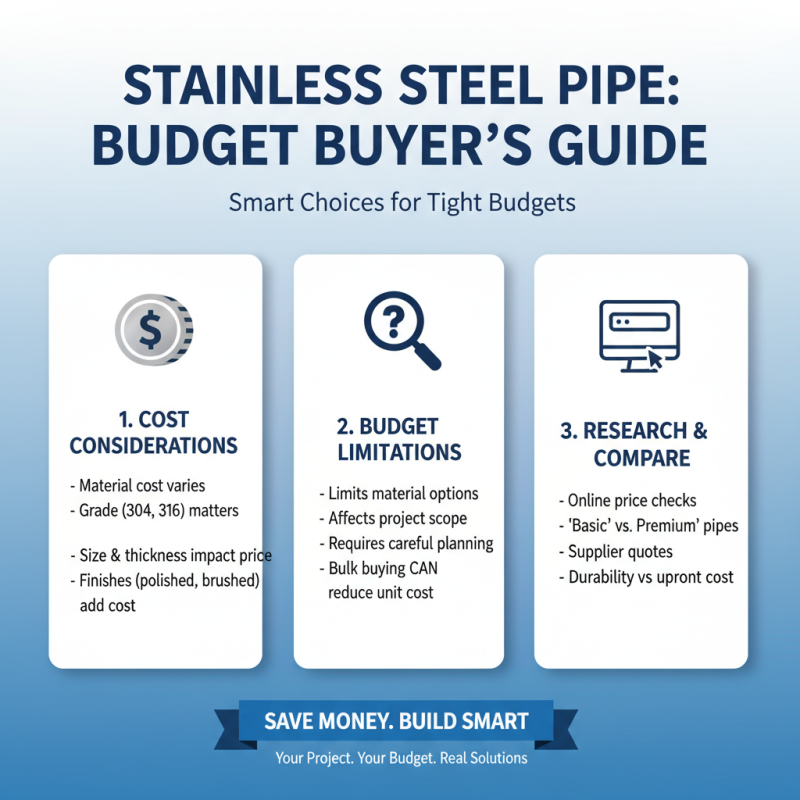

When tackling a project that requires stainless pipes, cost considerations play a significant role. A tight budget can limit options. This is often the reality for many businesses and DIY enthusiasts. It’s common to feel overwhelmed by the array of choices. Assessing costs early on can help in narrowing down selections. Look for basic price comparisons online; this can be a time-saver.

While aiming for budget-friendly options, don’t overlook quality. Higher initial costs might lead to better long-term savings. Low-priced pipes may have hidden expenses, such as maintenance or replacements. Reflecting on this can shift your focus from merely cutting costs to investing wisely. Consider the specific details of your project. Quality should not be sacrificed for price alone.

Keep in mind that there can be an emotional aspect, too. Choosing the right pipe can become frustrating when expectations clash with reality. It’s easy to get stuck thinking about what you can’t afford. This can sometimes cloud judgment. A balanced approach, weighing both budget and quality, is essential. Taking time to reassess your priorities can lead to more successful project outcomes.