Selecting the right hydraulic hoses is crucial for ensuring the efficiency and longevity of any hydraulic system. As industries increasingly rely on hydraulic technology, understanding the specific requirements for hydraulic hoses has become vital. According to a report by the International Journal of Fluid Power, improper hose selection can result in up to 30% of system failures, leading to costly downtimes. Such statistics underscore the necessity for professionals to be equipped with knowledge and strategies for selecting suitable hoses for their applications.

Industry expert Dr. John Smith, a renowned figure in hydraulic engineering, emphasizes, "Choosing the correct hydraulic hoses is not just about compatibility; it's about ensuring the safety and effectiveness of the entire hydraulic system." His insight highlights that every application demands careful evaluation of factors such as pressure ratings, temperature ranges, and material compatibility to prevent failures. By adhering to a systematic approach, engineers can mitigate the risks associated with incorrect hose selection, ultimately enhancing operational reliability and performance in various equipment and machinery.

When it comes to hydraulic hoses, understanding the different types available is critical for ensuring the efficiency and longevity of your equipment. Hydraulic hoses are primarily categorized based on their construction, including the materials used and the design standards they adhere to. Common types include rubber hoses, thermoplastic hoses, and stainless steel braided hoses. Each type has its own advantages; for instance, rubber hoses are flexible and cost-effective, while thermoplastic hoses offer higher resistance to chemicals and extreme temperatures, making them suitable for specialized applications. According to a report by the Hydraulic Institute, the global hydraulic hose market is projected to grow at a CAGR of 4.5% from 2021 to 2028, reflecting the increasing demand for advanced hydraulic systems across various industries.

Another important factor to consider when selecting hydraulic hoses is their pressure rating and size. Hoses are rated for specific maximum pressure limits, denoted as the working pressure, which should exceed the typical operational pressure in which it will be used. Additionally, the size, which includes both the inner diameter and overall diameter, plays a crucial role in determining flow rates and compatibility with fittings. A 2020 study from the Fluid Power Journal highlighted that improper sizing is one of the leading causes of hydraulic system failures, underscoring the need for careful evaluation prior to selection. Understanding these distinctions will help you choose the right hydraulic hose that meets the specific needs of your application and enhances overall system performance.

When selecting hydraulic hoses for your equipment, there are several key factors to consider to ensure optimal performance and safety. One of the most critical aspects is the hose's pressure rating, which should always exceed the maximum pressure your equipment will exert. According to industry reports, approximately 20% of hydraulic hose failures stem from using hoses with insufficient pressure ratings. Therefore, understanding the specific operating conditions and potential pressure spikes is crucial in making an informed choice.

Another important consideration is the hose material and construction. Different applications require different materials to withstand various environmental factors such as temperature, abrasion, and chemical exposure. For instance, a study by the Hydraulic Institute highlighted that hoses made from synthetic rubber can offer better durability and resistance to harsh conditions compared to traditional rubber hoses. Additionally, the correct choice of fittings and connection types is essential to prevent leaks and ensure a secure assembly. Given that improper fittings can cause up to 30% of hydraulic system failures, investing time in selecting the right components can significantly enhance the longevity and reliability of your hydraulic systems.

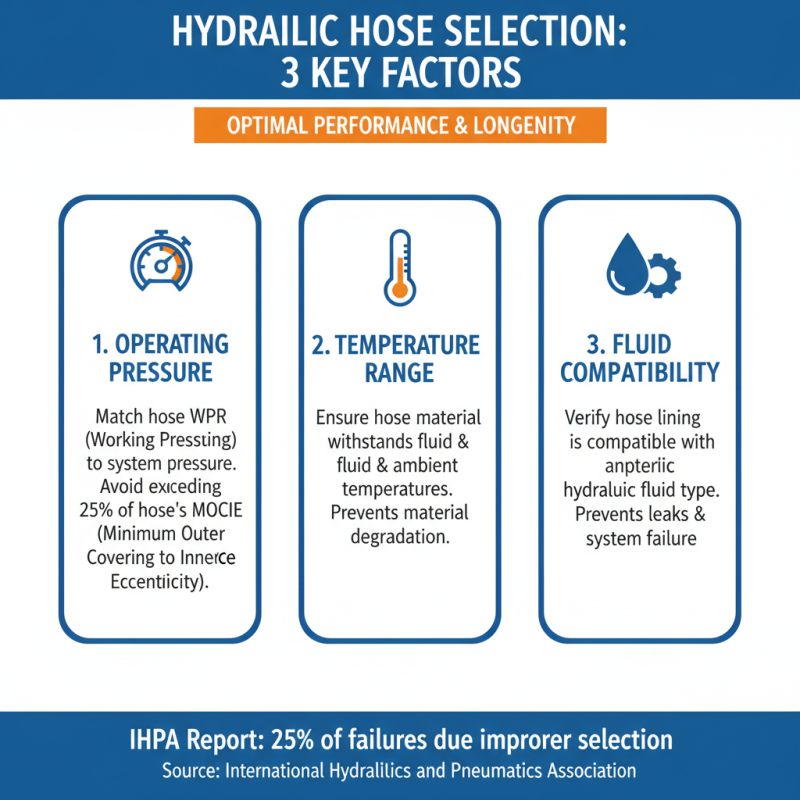

When selecting hydraulic hoses for your equipment, evaluating hose compatibility with your equipment's specifications is crucial to ensuring optimal performance and longevity. According to a report by the International Hydraulics and Pneumatics Association (IHPA), approximately 25% of hydraulic system failures are attributed to improper hose selection. This statistic underscores the importance of thoroughly understanding the specifications required for your system, including operating pressure, temperature range, and fluid compatibility.

To effectively determine the compatibility, first assess the application requirements of your equipment. This includes understanding the hydraulic fluid type, the physical environment in which the hose will operate, and the required bend radius. According to a survey from the Hose Manufacturers Association, 40% of equipment failures occur due to hoses not capable of withstanding the hydraulic fluid used, which emphasizes the need to review fluid compatibility charts or data sheets. Choosing hoses that align with the manufacturer's recommendations can enhance safety and reliability, mitigating risks associated with leaks or bursts.

Furthermore, consider the hose construction materials and reinforcement types specified for your application. For example, hoses reinforced with braided steel or those made of thermoplastic materials may offer different levels of flexibility and resistance to wear and tear. The American Society of Mechanical Engineers (ASME) highlights that proper hose material selection can improve both the efficiency and safety of hydraulic systems, furthering the longevity of equipment and minimizing maintenance costs throughout its lifecycle.

When selecting hydraulic hoses, understanding the operating conditions and environment is crucial to ensure optimal performance and longevity. According to a report from the Hydraulic Hose Association, approximately 30% of hose failures are attributed to environmental factors such as temperature fluctuations, exposure to chemicals, and mechanical wear. Therefore, one must assess the ambient conditions the hoses will encounter. For instance, high temperatures can lead to hose deterioration, while extreme cold can affect flexibility and increase the risk of cracking.

The type of materials in the hose must also align with the operating environment. Hoses exposed to high levels of UV radiation or extreme temperatures may require specific types of protective covers or compositions. The ISO 18752 standard emphasizes the importance of selecting hoses that meet specific pressure and temperature ratings based on the operational context. Evaluating these parameters not only aids in enhancing the efficiency of hydraulic systems but also dramatically reduces the risk of unexpected failures, contributing to safer operations and reduced downtime, which can cost industries millions annually. In fact, data indicates that downtime due to hydraulic hose failures can range from $5,000 to $20,000 per incident, emphasizing the criticality of diligent hose selection practices.

| Tip No. | Tip Description | Operating Conditions | Environmental Considerations |

|---|---|---|---|

| 1 | Determine the required hose pressure rating | Maximum working pressure | Temperature extremes |

| 2 | Choose the right hose diameter | Flow rate requirements | Physical space constraints |

| 3 | Identify fluid compatibility | Chemical properties of the fluid | Potential for contamination |

| 4 | Consider the hose's bend radius | Installation layout | Vibration and movement |

| 5 | Evaluate temperature range | Operating temperature | Seasonal changes |

| 6 | Assess the hose cover material | Abrasion resistance | UV exposure |

| 7 | Check for regulatory compliance | Industry standards | Risk management requirements |

| 8 | Review the hose assembly methods | Ease of installation | Maintenance access |

| 9 | Examine the hose length requirements | Distance between components | Complexity of routing |

| 10 | Plan for future expansion | Potential system upgrades | Changing operational needs |

Proper hose maintenance and inspection practices are crucial for ensuring the longevity and reliability of hydraulic hoses in any equipment. Regular inspection can help identify wear and potential failures before they lead to equipment downtime or costly repairs. Signs of abrasion, cracks, or bulges on the hose should be checked frequently, as these are indicators that the hose may be near the end of its service life. Keeping hoses clean and free of contaminants will also enhance their performance and reliability.

When choosing hydraulic hoses, consider longevity as one of your top priorities. Select hoses that are rated for the pressure and temperature conditions they will operate under. Additionally, pay attention to the environment where the hoses will be used; factors like exposure to chemicals, extreme temperatures, or physical wear can significantly impact hose performance. Implementing a regular maintenance schedule that includes checking for leaks and testing the hydraulic system can save time and money in the long run.

Ultimately, investing in the right hydraulic hoses and adhering to proper maintenance practices not only extends the lifespan of the hoses but also ensures safe and efficient operation of your machinery. Regular training for staff on best practices for hose care and inspection can further mitigate risks and promote a proactive maintenance culture within your operation.