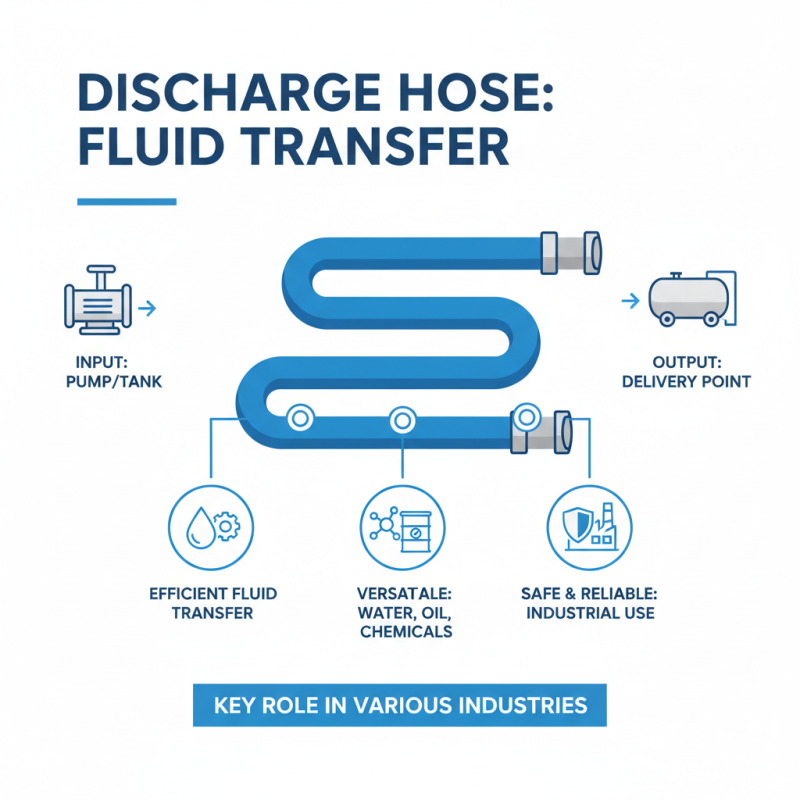

In the world of fluid transfer, the discharge hose plays a crucial role. It acts as the final conduit in the transfer process, guiding fluids away from pumps and containers. Without a reliable discharge hose, the efficiency of any fluid operation can suffer.

A discharge hose must be in good condition to prevent leaks. Any damage can lead to significant fluid loss and environmental hazards. This component must withstand various pressures and chemical compositions. The right materials ensure durability and safety.

Reflecting on its importance, one might overlook the discharge hose in favor of other equipment. However, its functionality is essential for seamless operation. Choosing the right discharge hose can make a major difference. Understanding its value is key to effective fluid management.

A discharge hose plays a crucial role in fluid transfer systems. It is specifically designed to move liquids safely and efficiently from one point to another. The right material and construction ensure that the hose can handle various types of fluids, including water, oil, and chemicals. This flexibility makes it indispensable in many industries.

When using a discharge hose, the connectors and fittings must match both the hose and the equipment. Incorrect connections can lead to leaks and spills. These issues can create safety hazards and environmental concerns. Additionally, the hose length should be appropriate for the distance needed. Longer hoses may cause pressure drops, affecting fluid flow.

Regular inspections are essential for maintaining the discharge hose. Check for cracks, wear, or damage that might compromise performance. A small issue can lead to a significant failure during operation. Understanding these factors helps in selecting the proper discharge hose. Careful consideration ultimately enhances efficiency in fluid transfer processes.

Discharge hoses play a crucial role in fluid transfer. They must be flexible yet durable. This combination allows them to handle various fluids without leaking. High-quality materials enhance their strength. However, not all hoses meet these essential criteria.

One key feature is the hose's resistance to temperature changes. Many hoses struggle with extreme heat or cold. This can lead to deformation or bursting. A good discharge hose maintains performance under diverse conditions. It should also resist abrasion and corrosion. These factors can wear down a hose quickly.

Proper fittings are another important aspect. They ensure secure connections, preventing spills. Some hoses lack adequate fittings, leading to frustration. The right design allows for easy attachment and detachment. Additionally, visibility in design can help in identifying flow direction. This small detail can prevent mistakes during operation. Ultimately, selecting the right discharge hose is vital for efficiency. A poor choice could create unnecessary problems.

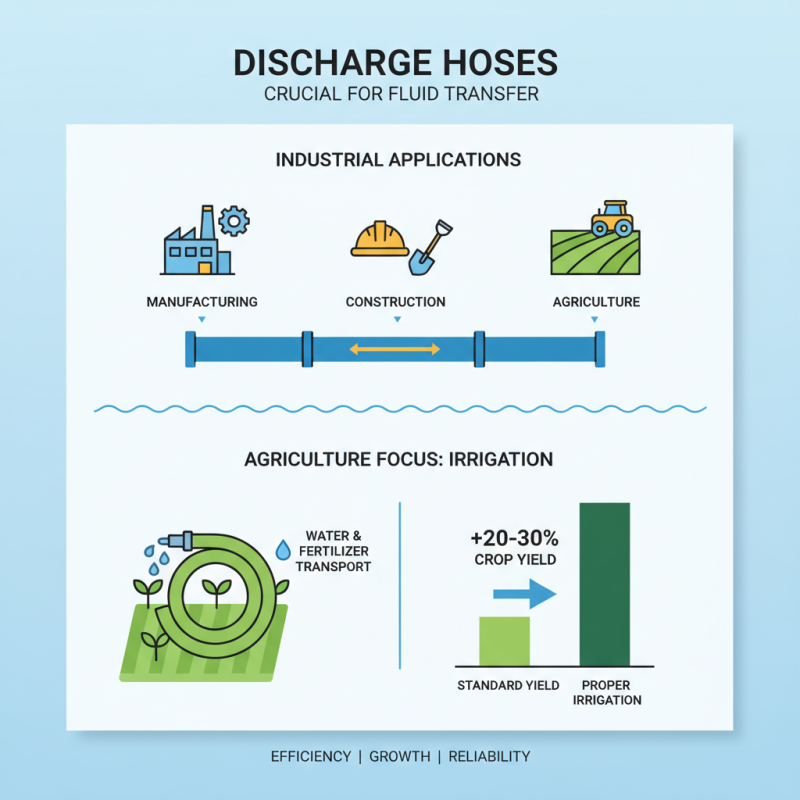

Discharge hoses are crucial in various industries for fluid transfer. Their applications range from agriculture to construction. In agriculture, flexible discharge hoses transport water and fertilizers. They ensure efficient irrigation, which boosts crop yields. Reports suggest proper irrigation can increase yield by 20-30%.

In construction, discharge hoses are vital for concrete pumping. They carry liquid concrete to desired locations. According to industry studies, using the right discharge hose can cut labor costs by up to 15%. The choices vary. Lightweight hoses are suitable for small jobs. Heavy-duty hoses are better for large-scale projects.

**Tip:** Regularly inspect hoses for wear and tear. A damaged hose can lead to leaks and costly delays.

Chemical industries also rely on specific discharge hoses. They transport corrosive fluids safely. According to safety reports, using compatible materials prevents accidents. Choosing the right hose material is essential. Miscommunication can lead to catastrophic failures.

**Tip:** Always refer to material safety data sheets when selecting hoses. Each application requires careful consideration.

Maintaining and using discharge hoses correctly is crucial for efficient fluid transfer. Regular inspection is necessary. Check for signs of wear, cracks, or leaks. Even a small damage can compromise the entire system. Ensure connections are secure. Loose fittings can lead to spills and decreased performance.

Proper storage is equally important. When not in use, coils should be stored in a cool, dry place. Avoid placing heavy objects on the hose. This can cause permanent deformation. Always clean the hose after use. Residual fluids can lead to corrosion and contamination. Sometimes, this maintenance process is overlooked until issues arise.

Training is an essential aspect as well. All users should understand how to handle the hose properly. Knowing the limits of pressure and temperature can prevent accidents. Encouraging best practices is a continuous effort. Mistakes can be costly, so regular discussions about safe usage and maintenance are beneficial. As you reflect on your practices, improvement should always be the goal.

When using discharge hoses for fluid transfer, safety is paramount. According to industry reports, improper handling and poor maintenance of hoses can lead to accidents. In fact, the National Institute for Occupational Safety and Health (NIOSH) cites that over 1,800 injuries occur annually due to hose-related incidents. This alarming statistic highlights the necessity of using high-quality hoses and following safety protocols.

Consider these tips for safety: Always inspect hoses for leaks or wear before use. Ensure they are properly secured and rated for the fluid being transferred. Use protective gear to prevent exposure to hazardous materials. Additionally, maintain a safe distance from the discharge area. Training personnel on emergency procedures is crucial, as well. Regular drills can be beneficial.

It's also important to remember that environmental factors can affect discharge hose performance. Extreme temperatures can degrade materials. Moreover, improper storage can lead to premature wear. Hoses should be kept in a dry, cool place to extend their life. Reflecting on these aspects can improve overall safety and efficiency in fluid transfer operations.