Choosing the right gas hose is crucial for safety and efficiency. A suitable gas hose ensures proper gas flow and prevents leaks. With so many options available, it can be overwhelming to make a decision.

Understanding the specifications of a gas hose is essential. Different gases require different types of hoses. For instance, propane gas hoses must withstand high pressure. On the other hand, natural gas hoses might have specific material requirements. These details can impact performance and safety.

Many people overlook the importance of regular checks on their gas hoses. A worn or damaged hose can lead to serious accidents. Thus, routine maintenance is necessary. It's also vital to ask questions about the hose's compatibility with your equipment. A small oversight could lead to costly repairs or dangerous situations. Remember, safety should always be your priority.

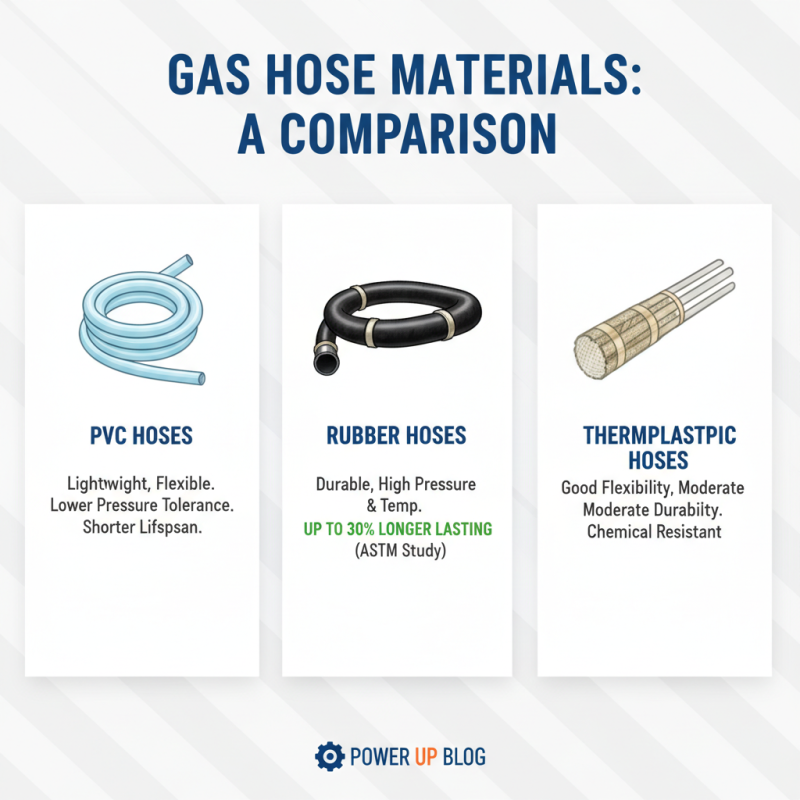

When selecting a gas hose, understanding the different types available is essential. There are several categories, including rubber, PVC, and stainless steel hoses. Rubber hoses are often favored for their flexibility and durability. They can withstand high temperatures and pressures, making them suitable for various applications. However, they can degrade over time if exposed to UV light or harsh chemicals.

PVC hoses are lightweight and easy to handle. They are typically less expensive but may not last as long as rubber options. This type is ideal for low-pressure applications and short-term use. On the other hand, stainless steel hoses offer excellent resistance to corrosion and are incredibly durable. They work well in harsh environments but can be heavier and more expensive.

Choosing the right hose is not just about material. The size and pressure rating also matter. A hose that is too small can restrict gas flow, impacting performance. Oversized hoses may lead to leaks or accidents. Many people overlook these details, leading to safety risks. Reflecting on these factors can lead to better, safer choices for any gas-related tasks.

| Type of Gas Hose | Applications | Material | Pressure Rating (PSI) | Length Options |

|---|---|---|---|---|

| Rubber Gas Hose | General gas applications, BBQs | Rubber | 350 PSI | 3 ft to 50 ft |

| PVC Gas Hose | Indoor use, camping | PVC | 300 PSI | 10 ft to 25 ft |

| Stainless Steel Gas Hose | High pressure, industrial use | Stainless Steel | 1500 PSI | 2 ft to 10 ft |

| Butane Gas Hose | Portable heaters, outdoor cooking | Rubber | 350 PSI | 5 ft to 15 ft |

Choosing the right gas hose is crucial for safety and efficiency. Several key factors come into play. First, consider the material of the hose. Common options include rubber and PVC. Rubber is durable and flexible, while PVC is lightweight. Each material has its strengths and weaknesses.

Tips: Always check for compatibility with your specific gas type. Using the wrong hose can lead to leaks or deteriorations.

Next, think about the hose size. It needs to fit your connection points securely. A hose that’s too thick may not fit properly, while one that’s too thin may not handle the pressure. Measure your connections carefully.

Tips: Keep spare hoses on hand. You never know when you might need a replacement, especially if one fails unexpectedly.

Lastly, evaluate the hose’s temperature rating. Some hoses handle high temperatures better than others. This is essential if you’re using it in a hot environment. Always refer to specifications for guidance.

Tips: Monitor the hose regularly for wear. A small crack can become a larger issue quickly. Maintaining hoses is key to safety.

Take your time to choose wisely. The right gas hose ensures smoother operations and peace of mind.

Choosing the right gas hose starts with understanding your gas type. There are many gases used in various applications. Each gas has specific requirements for compatibility. For example, propane and natural gas are common, yet they require different hoses. If the hose material is incompatible, it can lead to failures.

Pressure ratings are another critical consideration. Each hose is rated for a specific pressure range. Exceeding this limit can result in serious safety hazards. Regularly inspect your hose for visible wear or damage. Even slight abrasions can impact performance. Look for pressure ratings that exceed your system’s requirements for safety.

It’s easy to overlook these details when purchasing. Some might think any hose can work, but this isn't true. Not all materials perform the same way under pressure. It’s crucial to match the hose with the specific gas type and its properties. When in doubt, consulting with professionals can save time and avoid mistakes.

When it comes to selecting a gas hose, the material matters greatly. Common materials include PVC, rubber, and thermoplastic. PVC hoses are lightweight and flexible, but may not withstand high pressure. Rubber hoses, on the other hand, are known for their durability. They handle both pressure and temperature extremes effectively. According to a study by the American Society for Testing and Materials (ASTM), rubber hoses can last up to 30% longer than their PVC counterparts in similar conditions.

Safety is another crucial factor. Gas hoses must resist chemical degradation and wear. A report from the National Fire Protection Association (NFPA) emphasizes that improper materials can lead to leaks. These leaks can be hazardous, causing fires or explosions. In situational assessments, thermoplastic materials have shown acceptable performance in terms of safety and flexibility. Still, the risk of failure under extreme temperatures remains a concern.

One must consider specific applications before making a choice. Are you using it outdoors? Will it be exposed to UV light? Not every hose suits every environment. In some heavy-duty applications, users reported unexpected failures, forcing them to reassess their choices. Evaluating the right hose material can significantly impact durability and safety. Making an informed decision can prevent costly mistakes in the long run.

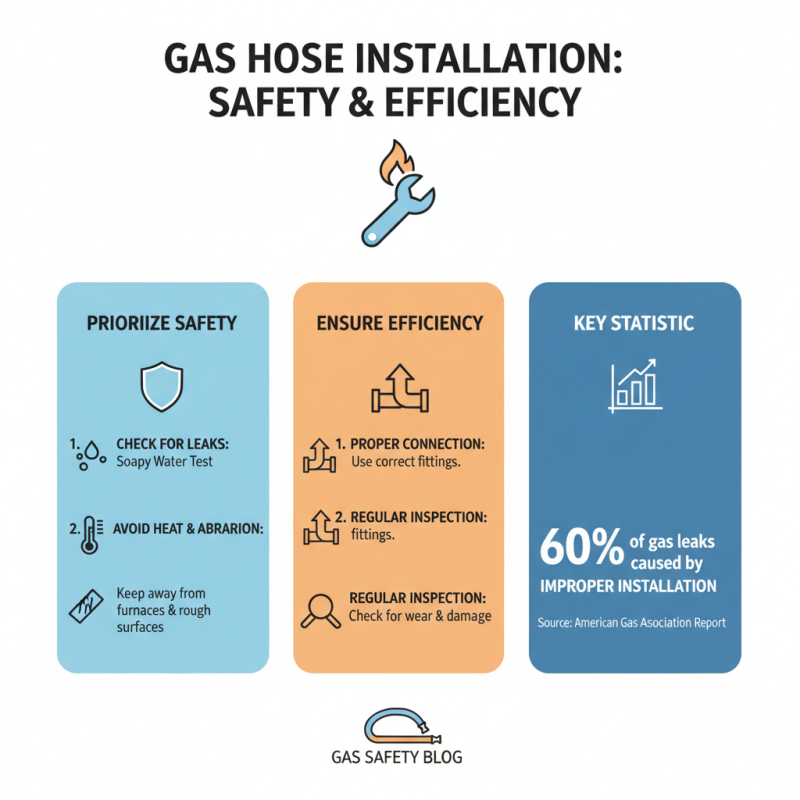

When installing gas hoses, it's crucial to prioritize safety and efficiency. A report from the American Gas Association highlighted that improper installation is a leading cause of gas leaks. Each connection should be checked for leaks using appropriate methods, such as soapy water tests. The installation environment is equally important; hoses should be kept away from heat sources and abrasive materials to prevent wear and tear.

Regular maintenance extends the lifespan of gas hoses. The National Fire Protection Association recommends inspecting hoses at least every six months. Look for signs of crackage or corrosion. Even small issues can lead to big problems. A recent survey revealed that over 30% of users neglect routine checks, which can jeopardize safety. Documentation of inspections is vital, as it helps identify recurring issues. This can inform future maintenance needs and installation practices. It’s okay to reevaluate your methods. Ignoring such considerations can be a costly oversight.