Choosing the right materials is crucial in piping systems. Among these, stainless steel fittings stand out significantly. They offer exceptional durability and resistance to corrosion. According to a recent report by the International Stainless Steel Forum, these fittings can last over 25 years in harsh environments. This longevity helps reduce replacement costs and maintenance efforts, making them a smart investment.

In industries like construction and manufacturing, the demand for stainless steel fittings continues to rise. They withstand extreme temperatures and pressures. A study published in the Journal of Materials Science revealed that stainless steel fittings maintain their integrity under tough conditions better than their plastic counterparts. However, some may overlook them due to their initial cost. It's essential to balance short-term expenses with long-term benefits.

Moreover, while stainless steel fittings are robust, they are not invincible. Factors like improper installation and maintenance can lead to failure. Understanding these challenges is critical for ensuring longevity. A proactive approach can mitigate risks and enhance the lifespan of fittings. In the end, the choice of stainless steel fittings reflects a commitment to quality and reliability in an ever-demanding industry.

Stainless steel is a popular choice for fittings due to its exceptional durability and longevity. Its unique composition plays a vital role in this. Stainless steel contains chromium, which forms a protective oxide layer. This layer prevents rust and corrosion, making it ideal for various environments. The properties of stainless steel are particularly beneficial in industries such as construction and plumbing.

When selecting stainless steel fittings, consider their quality. Look for fittings made with a high percentage of chromium and nickel. These elements enhance corrosion resistance. Even small variations in composition can impact performance. Always choose fittings that meet industry standards for safety and reliability.

Tips: Regular maintenance is key. Clean fittings periodically to remove any buildup. This simple step can extend their life significantly. Avoid exposing stainless steel to harsh chemicals whenever possible. Remember that sustained exposure can wear down the protective layer. These small actions lead to greater longevity.

When selecting stainless steel fittings, industry standards are crucial. These standards guide manufacturers on quality and safety. They ensure that every fitting can withstand harsh conditions. For instance, ASTM and ASME standards specify the required chemical composition. This helps in reducing corrosion and enhancing durability. Following these guidelines can prevent costly failures.

It's not just about meeting a standard; it's about the implications of not adhering to them. Lack of compliance can lead to significant issues, like leaks or breakages. The long-term effects of these failures can be dire, especially in critical systems. Moreover, not all manufacturers may consistently meet these standards. This inconsistency can leave users in a vulnerable position.

Design and application are key in choosing the right fittings. A fitting that works well in one environment might fail in another. Understanding the specific requirements of each application is vital. Relying solely on general standards can be misleading. Users must reflect on their unique needs and the environment in which the fittings will be used.

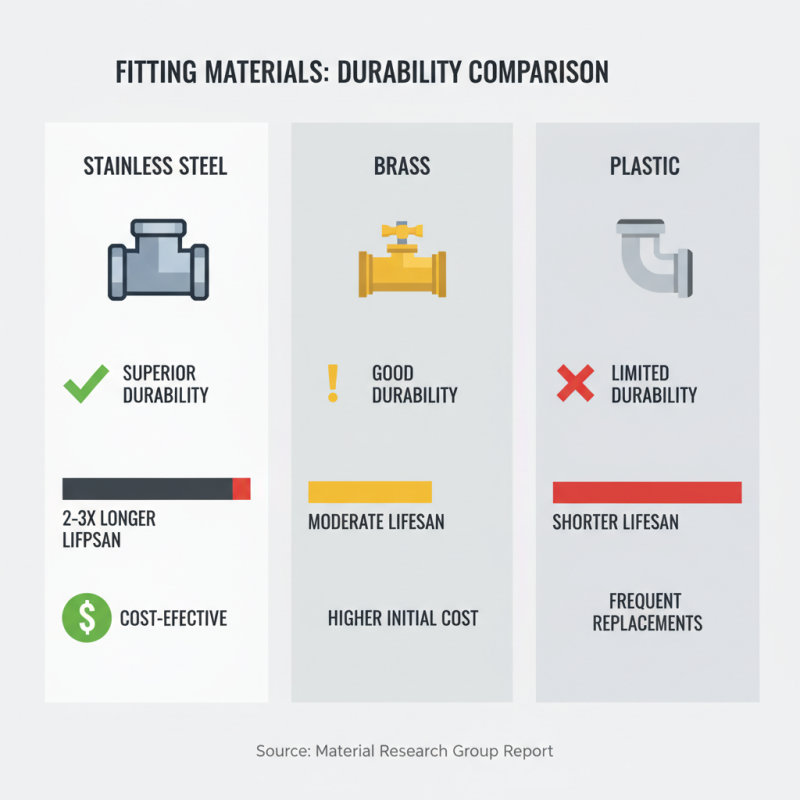

When choosing fittings, material matters. Stainless steel is often preferred for its durability. A comparative analysis shows that stainless steel outperforms materials like plastic and brass in various applications. According to a report by the Material Research Group, stainless steel fittings have a lifespan that is two to three times longer than that of plastic. This durability means fewer replacements, which is cost-effective over time.

However, it’s important to consider the environment. Stainless steel can be over-engineered for some applications, leading to unnecessary expenses. Also, if not properly cared for, stainless steel can develop corrosion, especially in coastal areas. In contrast, brass fittings might be easier to install in certain situations due to their malleability, but they tend to corrode faster. A study from the National Institute of Standards indicates that brass can lose structural integrity much sooner than stainless steel in harsh conditions.

Ultimately, the choice of material depends on specific needs. For high-pressure systems, stainless steel is often the clear choice. Yet, designers must assess project requirements carefully. Over-relying on one material can lead to overspending or performance issues. Balancing cost, material properties, and application is key to successful fittings design.

When considering fittings for various projects, stainless steel emerges as a top choice. This material offers longevity that few alternatives can match. Stainless steel fittings resist corrosion effectively, even in harsh environments. You can trust them to endure both time and wear. Moreover, their strength ensures reliability under high pressure.

Lifecycle cost analysis shows that stainless steel can provide economic advantages over time. While the initial investment may be higher, maintenance costs are significantly lower. They require less frequent replacements, which can save money in the long run. Imagine needing to replace fittings every few years. With stainless steel, that worry disappears. Yet, it’s important to recognize that not everyone sees the immediate benefits.

Some may question the upfront costs without considering future savings. This shift in perspective can be challenging. However, choosing stainless steel can simplify maintenance tasks and reduce downtime. Every time you replace a fitting, consider the hidden costs involved. Finding durability in fittings is crucial, and stainless steel serves that need well.

Stainless steel has become a staple in various industries. Its unique properties significantly enhance performance and durability. For instance, a report from the International Stainless Steel Forum notes that stainless steel can withstand corrosive environments. This makes it ideal for applications in marine and chemical industries. A study revealed that using stainless steel fittings increased the lifespan of pipelines by over 40%. This is crucial when projects require long-term investment.

In the food processing sector, stainless steel is preferred for its hygiene and safety features. According to the Food and Drug Administration, stainless steel surfaces reduce contamination risks. Many successful installations have been noted, demonstrating its effectiveness in maintaining cleanliness and safety. However, some facilities still struggle with initial costs. The choice might seem expensive upfront. But the long-term savings in maintenance and replacements speak volumes.

The construction industry also benefits from stainless steel’s strength. Buildings and infrastructure projects incorporate stainless fittings to ensure structural integrity. A survey indicated that over 60% of engineers favor stainless steel for critical applications. Yet, there are challenges with sourcing. Some suppliers may not meet quality standards. This creates gaps in reliability. Overall, the success stories of stainless steel in industry highlight its importance.

| Application Area | Material Used | Benefits | Challenges Addressed |

|---|---|---|---|

| Oil and Gas Pipelines | 304 Stainless Steel | Corrosion resistance, high tensile strength | Extreme environmental exposure, pressure |

| Pharmaceutical Manufacturing | 316L Stainless Steel | Hygienic properties, non-reactive | Strict cleanliness standards, contamination risk |

| Food Processing | AISI 430 Stainless Steel | Durability, ease of cleaning | Food safety regulations, maintenance |

| Construction | Duplex Stainless Steel | High strength, resistance to pitting | Heavy loads, harsh weather |

| Marine Applications | AISL 2205 Stainless Steel | Resistance to saltwater corrosion | Severe saline conditions, biofouling |