When it comes to maintaining optimal performance in various industrial applications, selecting the right vacuum relief valve is crucial. A vacuum relief valve is designed to protect equipment from vacuum conditions that may lead to catastrophic failures due to collapsing or implosion. As industries strive for efficiency and safety, understanding the key factors that influence the selection of a vacuum relief valve becomes imperative.

In this guide, we will explore the critical considerations that should be taken into account when choosing a vacuum relief valve tailored to your specific needs. From understanding different valve types to assessing pressure ratings and materials of construction, knowing how to navigate these options can significantly enhance the reliability and longevity of your system. By delving into the intricacies of vacuum relief valves, we aim to empower you with the information necessary to make an informed decision, ensuring that your operations run smoothly and safely.

Vacuum relief valves play a crucial role in maintaining the integrity and safety of various industrial systems. These valves are designed to prevent negative pressure from causing damage to equipment and piping, which can lead to costly downtime and repairs. According to a report by the Control Engineering magazine, improperly functioning vacuum relief valves can contribute to equipment failures amounting to $1.5 billion annually in the manufacturing sector alone. This staggering figure underscores the importance of selecting the right vacuum relief valve tailored to specific operational requirements.

The importance of vacuum relief valves is particularly evident in industries such as pharmaceuticals, food processing, and petrochemicals, where maintaining the right pressure balance is pivotal. A study by the International Journal of Chemical Engineering highlights that effective vacuum relief management can enhance process efficiency by up to 25%. This is achieved by ensuring that systems operate within optimal pressure ranges, thereby reducing the risk of product contamination and equipment malfunction. Understanding the specifications and performance criteria of different vacuum relief valves thus becomes essential for industries aiming to maximize productivity and maintain safety standards.

| Valve Type | Connection Size | Pressure Rating | Material | Temperature Range | Applications |

|---|---|---|---|---|---|

| Spring Loaded | 1 inch | 150 psi | Brass | -20°F to 250°F | Chemical Processing |

| Diaphragm | 2 inches | 100 psi | Stainless Steel | -40°F to 300°F | Food and Beverage |

| Vacuum Breaker | 3/4 inch | 50 psi | PVC | 32°F to 120°F | Irrigation Systems |

| Pneumatic Control | 1.5 inches | 200 psi | Aluminum | 0°F to 180°F | Industrial Vacuum Systems |

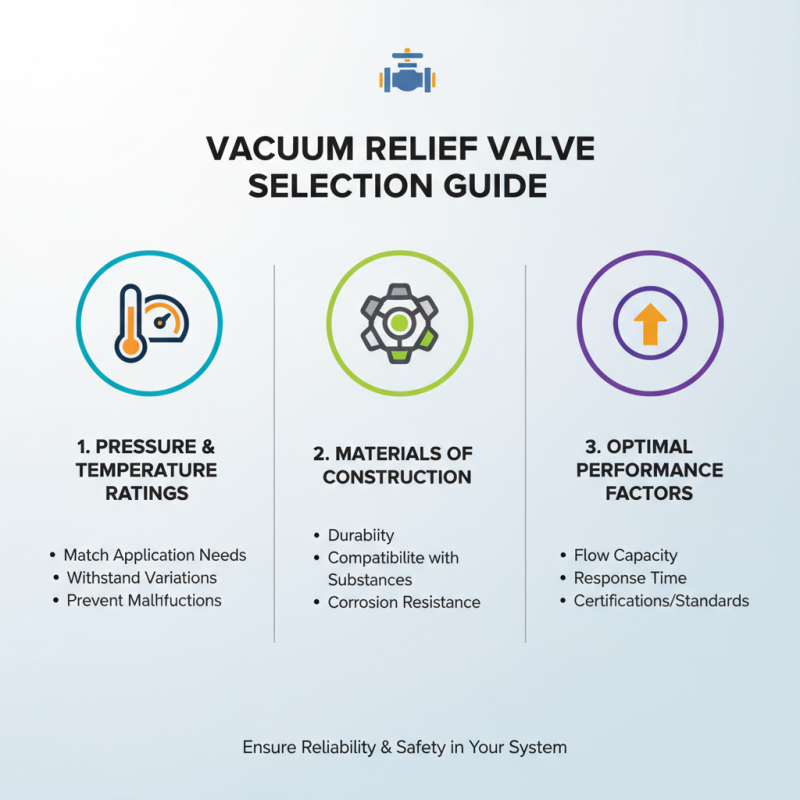

When selecting a vacuum relief valve, it is essential to consider several key factors to ensure optimal performance. First, the valve's pressure and temperature ratings must align with the specific application requirements. Understanding the operating conditions allows you to choose a valve that can withstand potential variations, preventing malfunctions or failures. Make sure to review the materials used in the valve construction, as this will affect its durability and compatibility with the substances being handled.

Another crucial factor is the valve's flow capacity. Selecting a valve with the appropriate flow rate ensures efficient pressure control without causing disruptions in the system. Additionally, consider the installation space and orientation, as some valves have specific requirements that may limit their installation options. Assessing the maintenance needs of the valve is also important; opting for a design that allows for easy access and servicing can enhance reliability over time. These considerations will help in choosing a vacuum relief valve that meets operational demands effectively.

When selecting a vacuum relief valve, understanding the various types and their specific applications is crucial for optimized performance. The two primary types are spring-loaded and diaphragm vacuum relief valves. According to a report from the International Society of Automation, spring-loaded valves are often preferred in systems requiring high flow rates, as they offer quick response times and can handle larger pressure differentials efficiently. These valves are typically used in industrial applications like chemical processing and oil refineries.

On the other hand, diaphragm valves provide more controlled and precise vacuum relief, making them suitable for applications involving sensitive materials. The 2022 Market Research report revealed that diaphragm vacuum relief valves have been seeing increased use in the pharmaceutical sector, where sterile environments are mandatory. Their design minimizes leakage and contamination risks, enhancing overall system integrity. By carefully evaluating the specific needs of your process—considering factors such as pressure settings, flow capacity, and application environment—you can choose the right type of vacuum relief valve to ensure safety and efficiency in your operations.

When selecting the right vacuum relief valve for your needs, it's essential to evaluate performance specifications meticulously. The valve's mass-flow-rate characteristics are crucial, as they significantly impact the dynamic performance of the system they are integrated into. Understanding how these parameters operate under various pressure conditions will help ensure optimal functionality and efficiency.

Moreover, the comparison of functional equivalency in various applications can provide insight into how different valves perform under similar operational scenarios. Just as advanced technologies in other fields, such as high-pressure pneumatic systems and innovative filtration processes, have transformed performance benchmarks, the right vacuum relief valve must align closely with the specific requirements of your application. This includes considering factors like response time, pressure settings, and compatibility with existing systems to maximize efficiency and reliability in your operations.

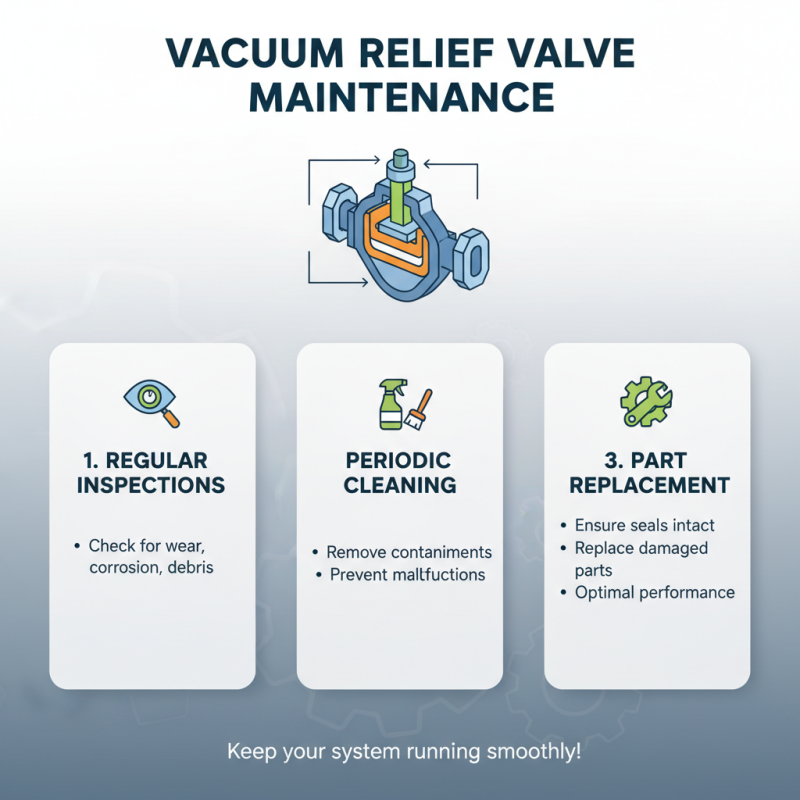

When it comes to maintaining vacuum relief valves, regular inspections are crucial to ensure their proper functioning. Check for any signs of wear, corrosion, or debris that may hinder the valve’s operation. Cleaning the valve periodically is essential, as contaminants can lead to malfunctions. Ensure that the valve seals are intact and replace any damaged parts promptly to maintain optimal performance.

Safety is another important consideration. Vacuum relief valves are critical for preventing vacuum-related hazards, such as implosions or equipment damage. Always adhere to the manufacturer’s guidelines regarding pressure limits and operational parameters. Installing pressure gauges can help monitor the system more effectively. Additionally, it’s wise to train personnel on the specific functions and maintenance procedures of the valves to enhance workplace safety and ensure compliance with operational protocols.