Choosing the right butterfly valve can be challenging. A butterfly valve controls flow with a simple disc mechanism. Understanding your specific requirements is essential for optimal performance.

Consider the fluid type you’ll be handling. Each fluid may react differently with materials used in butterfly valves. Pressure and temperature ratings also play a significant role in valve selection. Recognizing these factors helps avoid common mistakes.

Moreover, installation space and maintenance should not be overlooked. A poorly chosen valve may lead to inefficiencies or leakage. It’s vital to research thoroughly and consult experts if needed. Taking these steps can prevent costly consequences in the long run.

When selecting a butterfly valve, understanding the types available is essential. There are several kinds to consider: resilient seated, high-performance, and triple offset butterfly valves. Each type has unique features and applications, making the choice crucial for performance.

Resilient seated valves are common in water applications. They provide a good seal and are cost-effective. However, they may wear over time, especially in abrasive environments. High-performance valves handle higher pressures and temperatures. They often offer better efficiency but can be more expensive. Triple offset valves excel in high-pressure systems but require careful installation.

**Tips:** Always evaluate the media you will be controlling. Consider factors such as temperature and pressure. This can influence your valve choice significantly.

Another aspect to think about is size and fit. A valve that doesn’t fit properly can lead to leaks. It’s vital to measure accurate dimensions. This minimizes potential issues during installation and operation.

**Tips:** Engage with professionals if you're unsure. Their insights can aid in making a better decision. A small error can lead to bigger problems down the line.

This chart illustrates the distribution of different types of butterfly valves commonly used in various applications, showcasing their respective usage percentages.

Choosing the right butterfly valve involves careful consideration. The first key factor is the valve’s size. Correct sizing ensures efficient flow control. Too large or too small a valve can lead to pressure drops or excessive flow. Measuring the pipe diameter is essential. It’s a straightforward yet critical step.

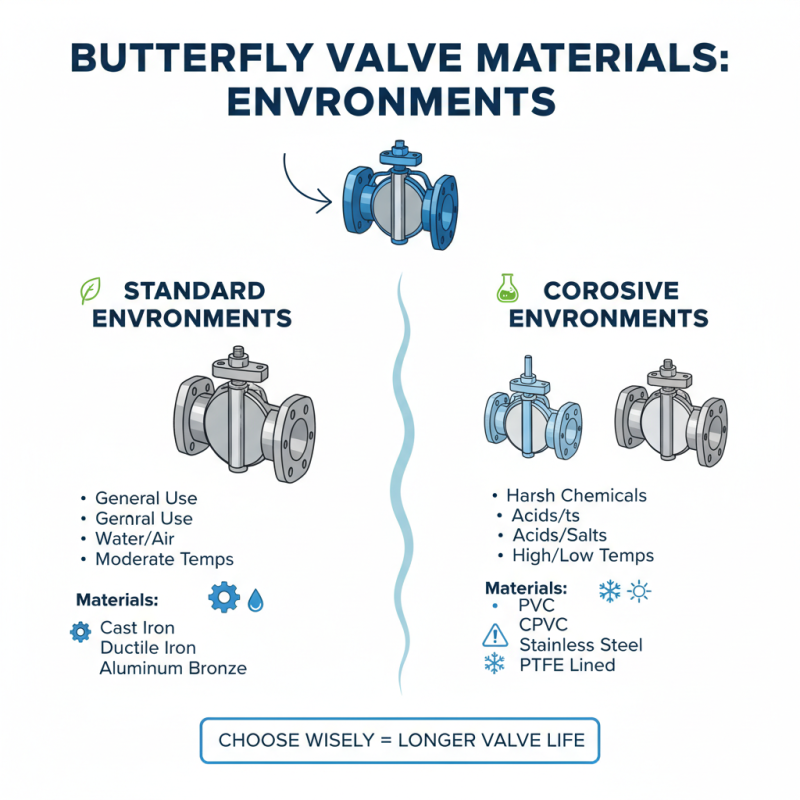

Another important factor is the material. Different environments require different materials. For example, stainless steel is durable in corrosive conditions. Plastic may be suitable for less demanding applications. Choosing the wrong material can lead to premature failure. It often necessitates unnecessary replacements or repairs, which can be costly.

Consider the valve's pressure rating as well. Each application has specific pressure requirements. A mismatch can lead to leaks or worse. Evaluating the operational environment is crucial. Reflect on whether the valve will be used for gas, liquid, or both. Each has unique challenges. Choosing a valve may seem simple, but overlooking these details can have significant consequences. Engaging with these factors thoughtfully can lead to better choices.

When selecting a butterfly valve, understanding your system requirements is crucial. Consider the fluid type. Is it corrosive or abrasive? This will influence the materials needed for the valve. Think about temperature and pressure ranges too. High temperatures may require special seals. Sometimes, overlooked details can lead to failures.

Next, evaluate the flow characteristics. Is your system requiring throttling or full flow? Different designs cater to various flow behaviors. Make sure to assess how your chosen valve responds under different conditions. Take time to analyze installation space. A too-tight fit may cause performance issues down the line.

You should also reflect on maintenance needs. Some valves require more regular attention than others. If overlooked, this can affect longevity. Consider operational automation as well. A manual valve may cost less initially, but is it worth it in the long run? Ultimately, creating a checklist of needs will help prevent costly mistakes.

Choosing the right butterfly valve hinges significantly on its material. The environment where the valve will operate plays a crucial role. For example, in corrosive environments, materials like PVC or stainless steel are often preferred. These options resist rust, prolonging the valve's lifespan.

Consider a more challenging situation. In high-temperature applications, standard materials may not suffice. Titanium or special alloys might be necessary. However, these materials can be expensive and require more maintenance. Finding a balance between durability and cost is often tough.

It's also worth noting that aesthetics aren't always the priority. Functionality should be the leading factor. A valve that looks good but fails in key applications isn't ideal. Before selecting, evaluate the specific demands of your environment. Reflect on what might work better.

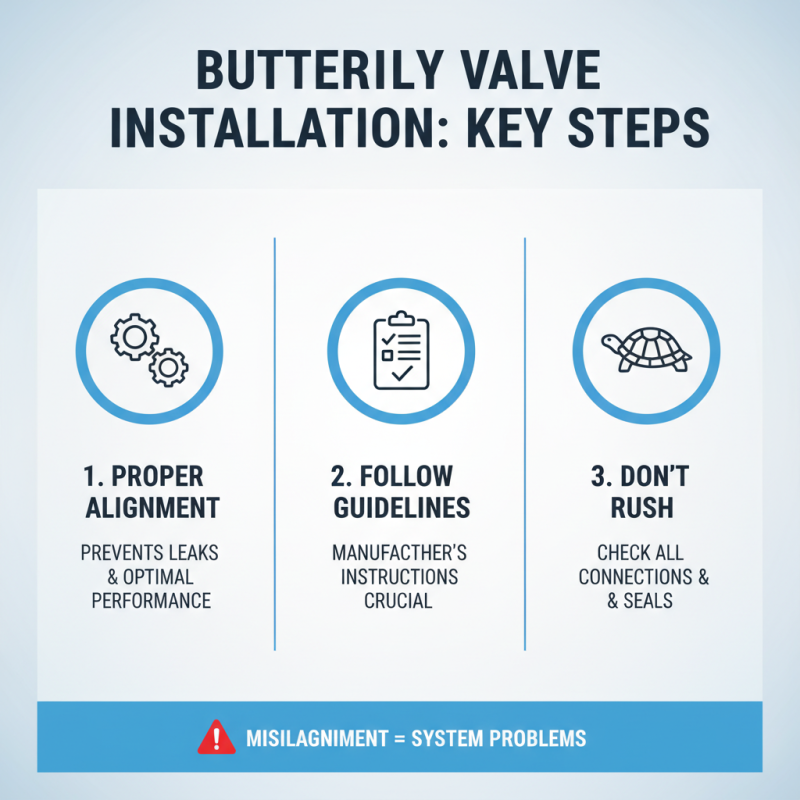

When it comes to installing butterfly valves, attention to detail is crucial. Proper alignment during installation helps prevent leaks and ensures optimal performance. Make sure to follow the manufacturer's guidelines carefully. A common mistake is rushing this process. Take your time to check all connections and seals. Misalignment can lead to significant problems later, affecting the entire system.

Maintenance is another critical factor in the longevity of butterfly valves. Regular inspections can help identify wear and tear early on. Lubrication is key, but too much can cause issues. Be mindful of the environment where the valve operates. Dust and debris can collect, leading to reduced efficiency. Establishing a routine for checking and cleaning can make a difference.

Ignoring these considerations can lead to complications. Sometimes, users might overlook minor signs of trouble, waiting until it escalates. This can lead to costly repairs or replacements. Regular training for those involved in installation and maintenance can help mitigate these risks. Being proactive is far better than dealing with consequences later on.