Selecting the right stainless steel pipe is crucial for any industrial project. The global demand for stainless steel pipes is projected to grow significantly. According to a recent report by Market Research Future, the market will exceed $18 billion by 2026. This growth highlights the importance of making informed decisions when choosing materials.

“Choosing the right stainless steel pipe can make or break a project,” says Dr. Emily Tran, a noted expert in materials engineering. Her insights emphasize the need for careful evaluation of specifications and applications. Each project has unique requirements that can affect the performance of stainless steel pipes.

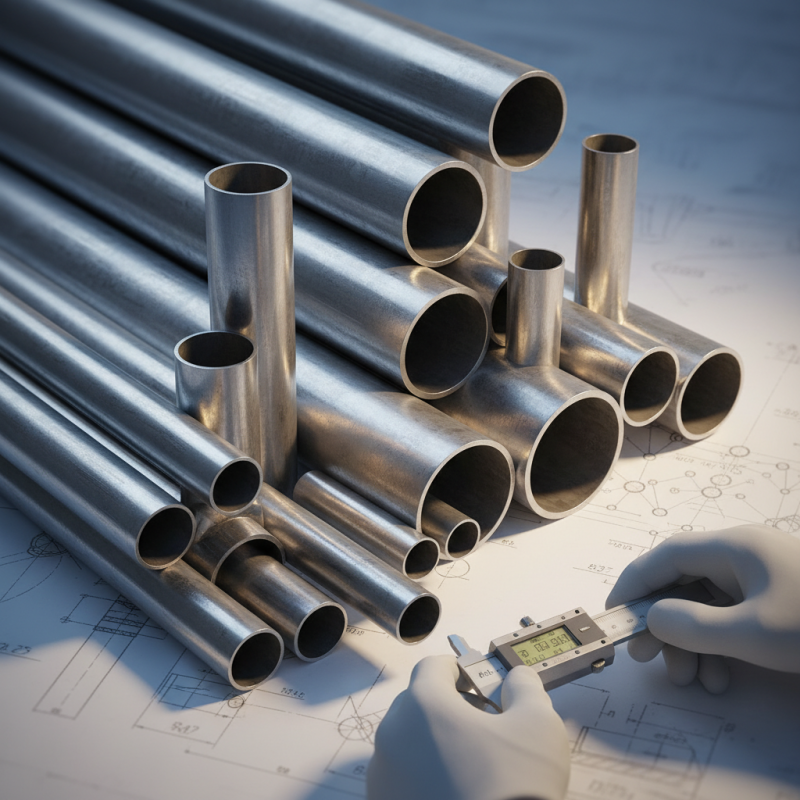

It's essential to consider factors such as thickness, diameter, and corrosion resistance. Not all stainless steel pipes are created equal. Some may be more prone to wear or corrosion than others. This variability makes it critical to assess individual project needs. A misstep could lead to costly delays or failures. Understanding the nuances of stainless steel pipes is not just beneficial; it's necessary for project success.

Choosing the right stainless steel pipe for your project requires understanding the different types available. Stainless steel pipes come in various grades. The most common are 304 and 316. According to industry reports, 304 stainless steel offers good corrosion resistance for many applications. However, for marine environments, 316 is essential due to its superior resistance to saltwater.

When selecting a stainless steel pipe, consider the pipe's diameter and wall thickness. Schedule 40 and Schedule 80 are standard options. Schedule 80 pipes have thicker walls, making them suitable for high-pressure applications. For fluid transfer, especially chemicals, the choice of grade is crucial. A misstep here could lead to costly failures.

Tip: Always check the environmental conditions before making a selection. This information can prevent unexpected issues later.

Another consideration is the pipe's finish. A smooth finish can enhance flow rate and reduce turbulence. A rough finish may cause maintenance challenges over time. Be mindful of how the finish impacts functionality.

Tip: Maintain a budget and plan for flexibility. It’s common to underestimate costs early in the design process. Remember, the wrong choice can lead to expensive rework.

Choosing the right stainless steel pipe involves a clear understanding of your project requirements. Consider factors like size, pressure ratings, and environmental conditions. According to industry reports, nearly 45% of piping failures are due to incorrect material selection or specifications. Understanding the application is crucial for decision-making.

Identify the medium the pipe will carry. This could be water, oil, or chemicals. Different environments demand specific grades of stainless steel. For instance, 304 and 316 grades are popular for their corrosion resistance. However, 316 is often favored in harsher conditions, such as marine environments. A research study indicated that 30% of projects underestimated environmental impacts on material selection, leading to premature failures.

Evaluate the necessary certifications and compliance standards for your project. Many industries have specific regulations that pipes must meet. Neglecting these requirements can lead to costly setbacks. It’s also vital to consider budget constraints. Sometimes, a lower-cost option may result in higher long-term expenses related to maintenance or replacement. It's a tough balance between upfront costs and future sustainability.

When selecting stainless steel pipes for your project, evaluating material properties is crucial. Different grades of stainless steel offer varying levels of corrosion resistance and strength. For instance, austenitic grades provide excellent durability in harsh environments. In contrast, ferritic grades might be more affordable but are less resistant.

Consider the intended application. Will the pipes face extreme temperatures or chemicals? Each scenario may require a specific grade. The thickness and diameter also influence the pipe's performance. Thinner pipes might not support heavy loads effectively, leading to potential failures.

Additionally, the surface finish should not be overlooked. A polished surface can resist buildup and corrosion better than a matte finish. However, achieving this finish can increase costs and processing time. Reflection on these trade-offs is crucial for long-term success in your project.

When selecting stainless steel pipes, cost and availability are critical factors. Different grades and types of stainless steel vary in price. For example, 304 stainless steel is often more accessible and affordable than 316 stainless steel. However, 316 offers superior corrosion resistance. Consider the project’s specific needs before making a choice.

Availability can impact project timelines. Some stainless steel options may not be readily in stock. This may lead to delays and increased costs. It’s essential to research local suppliers and their inventory. Sometimes, the less common grades can be harder to find. For urgent projects, sticking to more common materials could save time.

Additionally, it’s wise to evaluate your budget against the right material. Some projects may require premium options, while others might succeed with standard grades. Reflect on the long-term requirements of your project, too. Will the initial cost outweigh future repair expenses? Balancing cost, availability, and project needs may seem challenging, but it’s crucial for success.

Choosing the right stainless steel pipe involves understanding the installation and maintenance needs for specific applications. Stainless steel pipes come in various grades and sizes. For instance, grade 304 is widely used for its corrosion resistance. However, it might not be suitable for very high-temperature installations. This can lead to premature failures if not considered during the selection process.

Maintenance is another critical aspect. Though stainless steel pipes are generally low-maintenance, some environments can still cause issues. For example, in coastal areas, the chloride exposure can lead to pitting corrosion. Regular inspections can help identify potential weaknesses. The importance of routine maintenance cannot be overstated. In fact, a report by the American Society of Mechanical Engineers (ASME) indicates that neglecting maintenance can reduce a pipe's lifespan by up to 50%.

Installation considerations also play a vital role. Proper alignment and support are essential for long-term performance. Misalignment can create stress points, leading to leaks or even rupture. Additionally, installing a pipe without accounting for thermal expansion and contraction can result in significant problems over time. Understanding these details is crucial for a successful project. Ultimately, every project demands a tailored approach to the installation and maintenance of stainless steel pipes.