In the ever-evolving landscape of construction and manufacturing, the selection of materials plays a pivotal role in the success of any project. Among these materials, plastic tubing has gained significant acclaim due to its versatility and performance characteristics. According to a report by Freedonia Group, the demand for plastic tubing in the United States is expected to reach $8.8 billion by 2024, driven by its applications across various industries, including automotive, plumbing, and healthcare. This growth underscores the increasing recognition of plastic tubing as a reliable and efficient alternative to traditional materials.

The benefits of utilizing plastic tubing extend beyond mere cost-effectiveness. Industry studies have shown that plastic tubing offers superior resistance to corrosion, lightweight properties, and flexibility, making it an ideal choice for intricate design requirements. Furthermore, the plastic tubing market is projected to see a compound annual growth rate (CAGR) of 4.5% over the next several years, suggesting a robust and expanding demand for these essential components. As we explore the top 10 benefits of using plastic tubing for your projects, it becomes clear that this material not only meets but often exceeds industry standards, providing an array of advantages that can enhance both efficiency and durability in project execution.

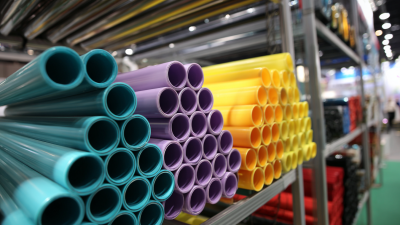

Plastic tubing is increasingly becoming the material of choice across various industries due to its remarkable versatility. Its adaptability allows it to be employed in a broad spectrum of applications ranging from automotive to medical. According to a report by Smithers Pira, the global market for plastic tubing is expected to reach $3.5 billion by 2025, driven by innovations in manufacturing processes and the increasing demand for lightweight and corrosion-resistant materials. This versatility is largely attributed to the different polymers available, such as polyethylene, PVC, and nylon, each offering unique properties that cater to specific project requirements.

In the medical field, for example, plastic tubing is essential for medical devices and equipment, where it can withstand sterilization processes while maintaining structural integrity. The flexibility of plastic tubing allows for ease of handling and installation, which is particularly valuable in situations that require intricate configurations. Moreover, the ability to customize plastic tubing in terms of diameter, wall thickness, and color further enhances its adaptability for various applications, making it an invaluable resource across sectors. As the demand for eco-friendly materials grows, the evolution of bio-based plastics also opens new avenues, ensuring that plastic tubing meets sustainable practices without compromising its performance.

Plastic tubing is quickly becoming the go-to solution for various projects due to its cost-effectiveness. When compared to traditional materials like metal or glass, plastic tubing offers significant savings in both material and installation costs. The lightweight nature of plastic allows for easier handling and transportation, reducing labor expenses and time delays during project execution. Furthermore, plastic tubing is often available in standardized sizes, which simplifies the purchasing process and minimizes waste.

In addition to its initial affordability, plastic tubing contributes to ongoing budget reductions through its durability and low maintenance requirements. Unlike metal, which can corrode over time, plastic is resistant to weathering and chemical damage, leading to a longer lifespan and fewer replacements. This durability translates into lower long-term costs, as projects need fewer repairs and replacements. By opting for plastic tubing solutions, project managers can achieve a balance between quality and cost, leading to more efficient budget management throughout the project's lifecycle.

Plastic tubing offers remarkable durability, making it an ideal choice for various projects. Unlike traditional materials, plastic tubing is resistant to corrosion, chemicals, and moisture, which ensures its longevity even in harsh environments. This inherent strength allows it to withstand significant pressure and stress, reducing the risk of breakage or failure during use. Consequently, projects that require reliable, long-lasting materials benefit immensely from the use of plastic tubing, minimizing maintenance and replacement costs over time.

Moreover, the lightweight nature of plastic tubing enhances its usability across different applications, from plumbing to electrical insulation. Easy to transport and install, it saves time and labor in project execution. The flexibility of plastic allows for bends and shapes that rigid materials cannot provide, opening up new possibilities for design and functionality. By opting for plastic tubing, project managers not only secure the durability that matters but also gain efficiency and adaptability, making it a smart investment for both short-term projects and long-term applications.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Resistant to wear, tear, and environmental factors, ensuring a long lifespan. | Industrial applications, outdoor wiring. |

| Chemical Resistance | Non-reactive with many substances, allowing safe transportation of various materials. | Chemical processing, laboratory equipment. |

| Lightweight | Easy to transport and handle, reducing overall project weight. | Packaging, construction. |

| Flexibility | Can be bent and shaped, making it suitable for various designs without breaking. | Automotive, manufacturing. |

| Cost-Effectiveness | Affordable compared to metal and other materials, saving on budget. | Retail, DIY projects. |

| Corrosion Resistance | Not prone to rust, ensuring longevity in humid or wet conditions. | Water treatment, plumbing. |

| Ease of Manufacturing | Simpler production processes, allowing for mass production with consistent quality. | Manufacturing, industrial supply chains. |

| Insulation Properties | Excellent insulator for electrical applications, enhancing safety. | Electrical wiring, electronics. |

| Wide Range of Sizes | Available in various diameters and lengths, making customization simple. | Custom designs, various applications. |

Plastic tubing offers significant advantages for a variety of projects, particularly when it comes to weight savings. Lightweight plastic tubing is increasingly favored in applications where traditional materials like metal and glass would typically be used. The reduction in weight not only makes handling and installation easier, but it also enhances overall project efficiency. This is especially beneficial in industries such as construction, manufacturing, and automotive, where reducing the weight of components can lead to lower transportation costs and improved energy efficiency.

Plastic tubing offers significant advantages for a variety of projects, particularly when it comes to weight savings. Lightweight plastic tubing is increasingly favored in applications where traditional materials like metal and glass would typically be used. The reduction in weight not only makes handling and installation easier, but it also enhances overall project efficiency. This is especially beneficial in industries such as construction, manufacturing, and automotive, where reducing the weight of components can lead to lower transportation costs and improved energy efficiency.

The lightweight nature of plastic tubing allows for greater flexibility in design and application. Engineers and designers can create structures and systems that utilize less material without compromising strength or durability. This has a domino effect, as lighter projects often require less robust supporting structures, thereby minimizing overall material use and costs. Moreover, with advancements in plastic technology, the tensile strength of tubing has improved, allowing it to withstand various pressures and conditions, making it a reliable choice in many demanding environments.

When it comes to project efficiency, the ease of installation provided by plastic tubing is a game-changer. Its lightweight and flexible nature makes handling and maneuvering during installation a breeze. Unlike traditional materials that may require specialized tools and techniques, plastic tubing often allows for simple cuts and connections using basic equipment. This user-friendly characteristic means that both novice DIY enthusiasts and experienced professionals can work with it seamlessly, reducing both time and frustration.

In addition, plastic tubing is designed to accommodate a variety of applications, from irrigation systems to plumbing. This versatility extends the ease of installation, as the material adapts well to different project requirements without compromising performance. Whether you're creating a complex system or a straightforward setup, the straightforward installation process of plastic tubing ensures that your projects can be completed efficiently, allowing for quicker progress and smoother workflows. The combination of accessibility and adaptability makes plastic tubing an essential choice for anyone looking to streamline their project operations.