Camlocks play a pivotal role in various industrial applications, offering rapid and reliable connections in fluid handling processes. According to a report by MarketsandMarkets, the global couplings market is projected to reach USD 9.82 billion by 2026, with camlocks being a significant contributor due to their durability and ease of use. These quick connect-disconnect devices are favored in industries such as

construction, agriculture, and oil & gas because they facilitate efficient workflow and reduce downtime. Research indicates that the adoption of camlocks can lead to a 30% decrease in assembly time compared to traditional threaded connections. As industries continue to prioritize efficiency and safety, understanding the unique benefits of camlocks is essential for optimizing operations and ensuring reliable fluid transport solutions.

Camlocks play a pivotal role in various industrial applications, offering rapid and reliable connections in fluid handling processes. According to a report by MarketsandMarkets, the global couplings market is projected to reach USD 9.82 billion by 2026, with camlocks being a significant contributor due to their durability and ease of use. These quick connect-disconnect devices are favored in industries such as

construction, agriculture, and oil & gas because they facilitate efficient workflow and reduce downtime. Research indicates that the adoption of camlocks can lead to a 30% decrease in assembly time compared to traditional threaded connections. As industries continue to prioritize efficiency and safety, understanding the unique benefits of camlocks is essential for optimizing operations and ensuring reliable fluid transport solutions.

Camlocks have gained significant traction in industrial applications, particularly when it comes to streamlining fluid transfer processes. According to a report by Grand View Research, the global market for camlock fittings is projected to reach $1.2 billion by 2025, driven by the increasing demand for efficient and reliable fluid transfer solutions.

One of the primary advantages of camlocks is their ease of use; they facilitate quick and secure connections without the need for specialized tools. This not only speeds up operations but also reduces the likelihood of leaks and spills, which can lead to costly downtime and safety hazards.

One of the primary advantages of camlocks is their ease of use; they facilitate quick and secure connections without the need for specialized tools. This not only speeds up operations but also reduces the likelihood of leaks and spills, which can lead to costly downtime and safety hazards.

Moreover, camlocks are highly versatile and can be used with a wide range of fluids, including chemicals, water, and oils. A study by the International Fluid Power Society emphasizes that using camlocks can improve the efficiency of fluid handling systems by up to 30%, reducing the time workers spend connecting and disconnecting hoses and fittings.

The durability and reliability of camlocks also ensure long-lasting performance in demanding environments, ultimately providing cost savings on maintenance and replacements. As industries continue to prioritize operational efficiency and safety, the adoption of camlocks will likely continue to rise, marking them as a crucial component in modern fluid transfer applications.

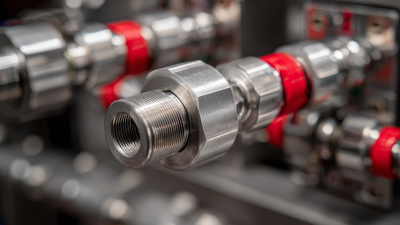

Camlock fittings are increasingly recognized for their enhanced safety features in industrial applications. These fittings are designed to provide a secure and reliable connection, minimizing the risk of leaks and spills. The unique locking mechanism of camlocks ensures that they stay securely attached even under pressure, which is particularly advantageous in environments where safety is paramount, such as construction and manufacturing.

In light of recent advancements, such as the introduction of innovative clamp systems, further improvements in safety and efficiency are on the horizon. These developments emphasize the importance of using robust fittings that meet industrial standards. By integrating safety-focused designs, companies can significantly reduce the likelihood of accidents, enhancing overall operational safety.

**Tips:** Always ensure that camlocks are properly inspected and maintained. Regular checks for wear and tear can prevent failures that might lead to hazardous situations. Additionally, when selecting camlocks, consider the specific requirements of your application to guarantee optimal performance and safety compliance.

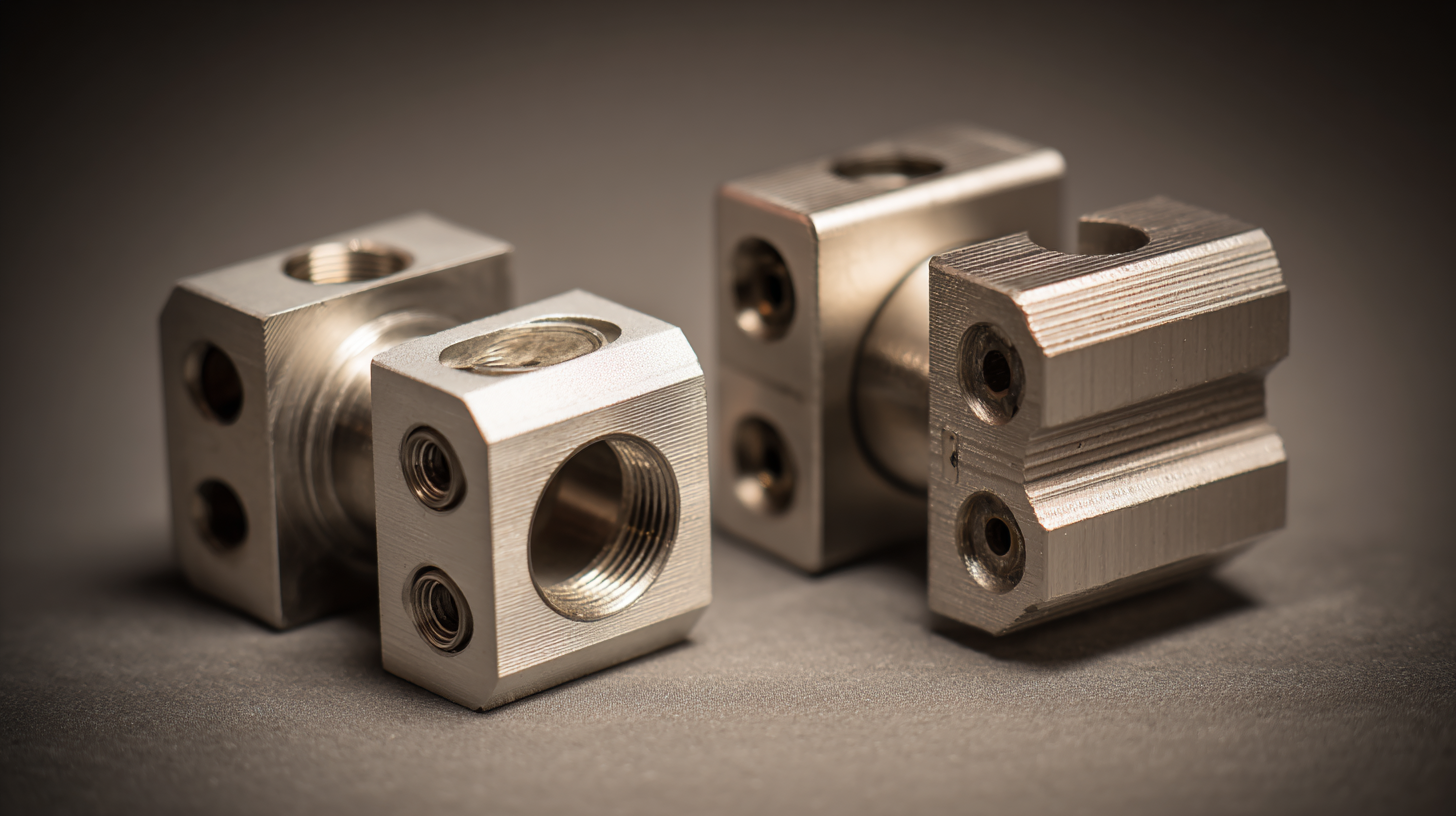

In industrial applications, the integration of camlocks can lead to significant cost savings, particularly concerning equipment connections. According to a report by the Fluid Power Journal, using camlocks can reduce the assembly time by up to 30%, streamlining operations that involve frequent coupling and uncoupling of hoses and fittings. This efficiency not only enhances productivity but also minimizes downtime, which can translate into lower operational costs over time.

Additionally, the Durability Test conducted by the Industrial Connection Association shows that camlocks have a lifespan that can exceed traditional fittings by 50%, reducing the need for frequent replacements. This long-term reliability ensures that investments in camlock systems are recouped quickly through operational savings and decreased maintenance requirements. Furthermore, the initial procurement costs of camlocks can be offset by these savings, making them a cost-effective choice in the long run.

**Tip:** When selecting camlocks, consider the material. Using stainless steel camlocks for corrosive environments can vastly extend the life of your equipment and reduce replacement costs.

**Tip:** Ensure proper training for staff on the right techniques for using camlocks to maximize their efficiency and lifespan—training can prevent common mishaps that lead to additional costs.

| Application Area | Cost Savings (%) | Time Efficiency (%) | Failure Rate Reduction (%) | Ease of Use (1-5) |

|---|---|---|---|---|

| Water Treatment Facilities | 30% | 25% | 15% | 4 |

| Chemical Processing | 25% | 30% | 20% | 5 |

| Oil and Gas | 20% | 20% | 25% | 5 |

| Food and Beverage | 15% | 15% | 10% | 4 |

| Pharmaceuticals | 35% | 40% | 30% | 5 |

Camlocks, also known as cam and groove couplings, are increasingly becoming indispensable in a variety of industrial applications due to their versatility and ease of use. One of the primary benefits of camlocks is their ability to facilitate quick and secure connections for transferring liquids and dry materials. In the agricultural sector, for instance, they enable efficient pumping of water, fertilizers, and pesticides, minimizing the time and effort needed for connection and disconnection. This efficiency not only streamlines operations but also enhances productivity across different processes.

In construction and manufacturing, camlocks play a crucial role in handling materials like cement, sand, and various chemicals. Their robust design ensures a tight seal that prevents leaks, which is vital for maintaining safety and compliance with environmental regulations. Additionally, the simplicity of their design allows for easy operation, reducing the risk of injury during heavy lifting or equipment loading. The adaptability of camlocks extends to industries such as food and beverage, where hygiene is paramount; camlocks can be cleaned easily, making them suitable for transferring liquid products while adhering to stringent quality standards.

The integration of camlocks in industrial applications has led to a significant enhancement in operational efficiency. According to a report by the Industrial Supply Association, the use of camlock fittings can reduce the time required for assembly and disassembly of hoses and piping systems by up to 50%. This swift connection process minimizes downtime, allowing for faster project turnaround and improved productivity. Industries such as chemical processing, agriculture, and oil and gas have widely adopted camlocks to streamline their operations and maintain high safety standards.

Furthermore, the reliability of camlocks contributes to operational efficiency. The report by the Fluid Control Institute indicates that improper fittings in fluid transfer systems account for nearly 30% of operational failures in industrial settings. By utilizing camlocks, which are engineered for quick and secure connections, facilities can significantly decrease the likelihood of leaks and equipment malfunctions. This not only prevents costly interruptions but also promotes a safer work environment, ultimately contributing to a more robust bottom line for businesses. Thus, camlocks serve as a critical component in enhancing operational capabilities across various industries.