Braided hoses have gained popularity across various industries due to their unique advantages. This versatile component combines strength and flexibility, making it ideal for many applications. From automotive systems to industrial machinery, braided hoses provide essential functionality.

Their design typically features multiple layers that enhance durability and resistance to high pressure. This construction minimizes risks of leaks or bursts, which can lead to costly downtime. Flexibility is another key benefit; braided hoses can bend and twist in tight spaces, which simplifies installation and use.

However, not all braided hoses are created equal. Some may not withstand extreme temperatures or harsh chemicals. Users must carefully assess their specific needs to select the right hose. Understanding these points can help avoid issues during operation. Braided hoses offer numerous benefits, yet selecting the right one is a crucial task.

Braided hoses are becoming essential in fluid transfer applications. Their structure offers impressive flexibility and strength. This is crucial in various industries, from manufacturing to automotive. With these hoses, users can ensure efficient fluid movement. They withstand high pressures while maintaining their shape. The durable exterior protects against abrasion and environmental factors. This enhances their longevity and reliability.

Another notable advantage is their resistance to kinking. A kinked hose can cause blockage and reduce flow. Braided hoses help prevent this issue and support continuous operation. Their lightweight design also contributes to easier handling and installation. Technicians can maneuver them without excessive strain. However, it's vital to consider compatibility with specific fluids. Not all braided hoses work well with every liquid. Users must conduct thorough research to avoid misapplications. Regular inspections are necessary to ensure optimal performance. Ignoring these checks may lead to unexpected failures.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Braided hoses are highly resistant to wear, tear, and environmental factors. | Industrial machinery, automotive |

| Flexibility | These hoses can bend and twist easily, allowing for easier installation. | Robotics, hydraulic systems |

| Pressure Resistance | Designed to withstand high pressure, reducing the risk of failure. | Oil and gas, chemical processing |

| Temperature Tolerance | Can operate in a wide range of temperatures without compromising performance. | Heating systems, HVAC |

| Corrosion Resistance | Braided materials provide superior resistance to corrosive substances. | Chemical transportation, marine applications |

| Lower Weight | Lighter than traditional hoses, contributing to reduced overall system weight. | Aerospace, automotive |

| Enhanced Safety | Less prone to damage and failure, leading to safer operation. | Construction, mining |

| Cost-Effectiveness | Long lifespan and durability lead to lower replacement costs over time. | Manufacturing, transportation |

| Versatility | Suitable for a wide range of fluids and applications. | Food & beverage, pharmaceuticals |

| Aesthetic Appeal | Offers a professional look for visible installations. | Consumer products, custom projects |

Braided hoses are known for their durability and flexibility, especially in harsh environments. These hoses can withstand extreme temperatures and pressures without compromising performance. Their sturdy construction makes them resistant to wear and tear, which is critical in challenging applications. For instance, in industrial settings with heavy machinery, they can endure abrasions from moving parts.

Flexibility is another key advantage. Unlike rigid hoses, braided hoses can bend and curve around obstacles, making installation easier. They adapt well to confined spaces, ensuring that setups remain organized. However, this flexibility can be a double-edged sword. In high-stress situations, if not properly secured, they may shift unexpectedly, leading to potential leaks.

The combination of durability and flexibility allows braided hoses to excel in various applications, from automotive systems to chemical processing. They thrive in environments that would typically degrade other materials. Still, users must regularly inspect them for signs of wear. Ignoring small issues could lead to bigger problems later. Balancing performance with regular maintenance is crucial for optimal use.

Braided hoses offer distinct advantages over standard hoses, especially when it comes to pressure resistance. Their construction features intertwining strands that provide additional strength. This design allows them to withstand higher pressure levels without bursting. For instance, in hydraulic applications, the ability to handle intense pressure can prevent failures and enhance system reliability.

However, there are moments when users underestimate the importance of proper installation. Incorrect fittings or inadequate securing can lead to dangerous leaks. This can offset the benefits that braided hoses provide. In agriculture, these hoses are frequently used for chemicals and irrigation. A small error in connection can result in costly spills or damage. Attention to detail is crucial here.

Furthermore, braided hoses are not completely immune to wear and tear. Environmental factors like UV exposure and extreme temperatures can affect their longevity. Regular inspection is essential to ensure they remain effective. Users must remember that even the best products need maintenance. A proactive approach can significantly extend their lifespan and performance.

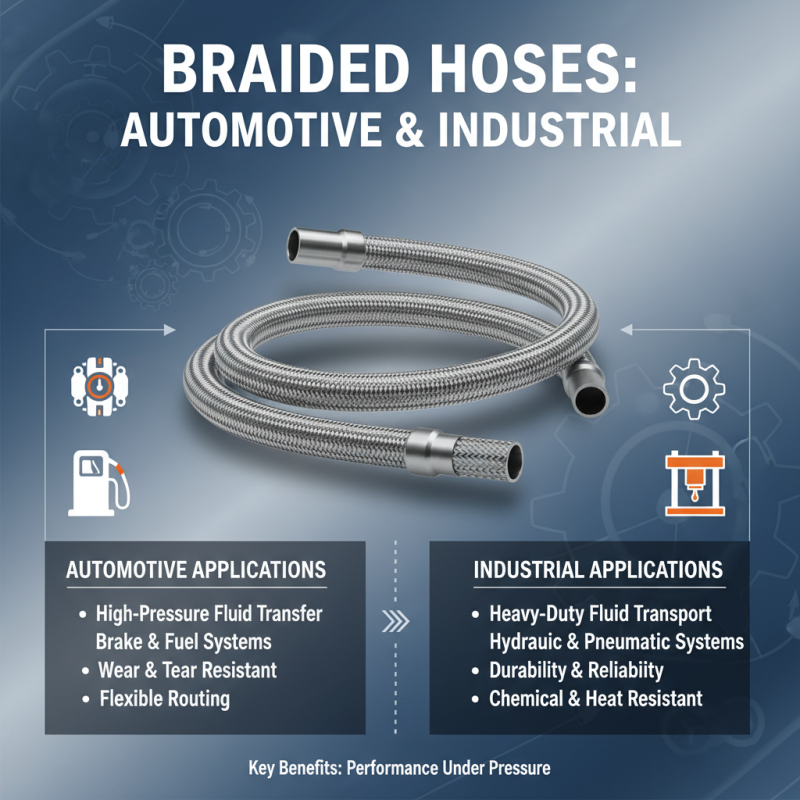

Braided hoses are essential components in both automotive and industrial applications. In vehicles, these hoses handle high-pressure scenarios. They ensure fluid transfer is safe and reliable. The braided construction makes them resistant to wear and tear. This is crucial for maintaining performance under pressure. Automotive engineers often rely on these hoses for brake and fuel systems. The flexibility they offer allows for complex routing in tight spaces.

In industrial settings, braided hoses are used to transport various substances. These range from water to chemical fluids. Their robust design withstands high temperatures and pressures. This makes them ideal for factories and manufacturing plants. However, not all braided hoses perform equally in every situation. Some may not be suitable for specific chemicals. Users must evaluate compatibility and application needs carefully. Despite their advantages, it’s important to monitor their condition. Any signs of wear can lead to safety hazards. Regular inspections are key to ensuring they function effectively over time.

The cost-effectiveness of braided hoses can be attributed to their materials and design. These hoses often consist of a combination of synthetic rubber and braided fibers. This blend enhances durability and resistance to wear. A recent industry report indicates that braided hoses can last up to five times longer than standard rubber hoses. This longevity reduces replacement costs significantly.

In various applications, including automotive and industrial, the use of braided hoses shows clear economic advantages. Many industries report a reduction in maintenance costs by up to 30% when switching to braided hoses. This shift often stems from fewer leaks and long-term reliability. However, some users still find that initial investments can feel high. The upfront cost may lead to hesitation among smaller companies.

While it's true braided hoses are generally more durable, not every situation warrants their use. For low-pressure applications, alternatives may suffice. It's essential to evaluate the specific needs of each project. Users should not overlook the factors that could influence performance and longevity. Careful analysis helps avoid costly missteps.

This chart illustrates the top 10 benefits of using braided hose across different applications, emphasizing cost-effectiveness and longevity.