When embarking on various projects, choosing the right materials can significantly influence the outcome and efficiency of your work. Among the numerous options available, plastic tubing stands out as a versatile and effective choice for a wide range of applications. Its unique properties combine durability, flexibility, and cost-effectiveness, making it an ideal candidate for numerous industries, from construction to medical devices.

The benefits of plastic tubing extend beyond mere functionality; its lightweight nature allows for easy handling and installation, while its resistance to corrosion and chemicals ensures longevity even in challenging environments. In addition, the availability of various sizes and shapes means that it can be tailored to meet specific project requirements, enhancing its utility across different scenarios. As we explore the myriad advantages of plastic tubing, it becomes clear why so many professionals and hobbyists alike lean towards this material for their projects.

Plastic tubing is increasingly recognized for its versatility and benefits across various applications. One of the primary advantages of plastic tubing is its lightweight nature compared to traditional materials such as metal or rubber. According to a report by the Plastics Industry Association, plastic provides a weight reduction of up to 50%, which not only simplifies handling and installation but also reduces transportation costs. This makes plastic tubing an excellent choice in industries ranging from construction to packaging, where efficiency is key.

Moreover, plastic tubing offers remarkable resistance to corrosion and chemicals, making it suitable for a wide range of environments. A study published in the Journal of Materials Science highlights that plastics can withstand various chemicals, providing an effective alternative where metal fittings would deteriorate or degrade. This chemical resistance is particularly beneficial in the pharmaceutical and food processing industries, ensuring safety and maintaining the integrity of contents. Overall, the advantages of plastic tubing in terms of weight, resistance, and adaptability make it an ideal solution for numerous projects, enhancing both performance and longevity.

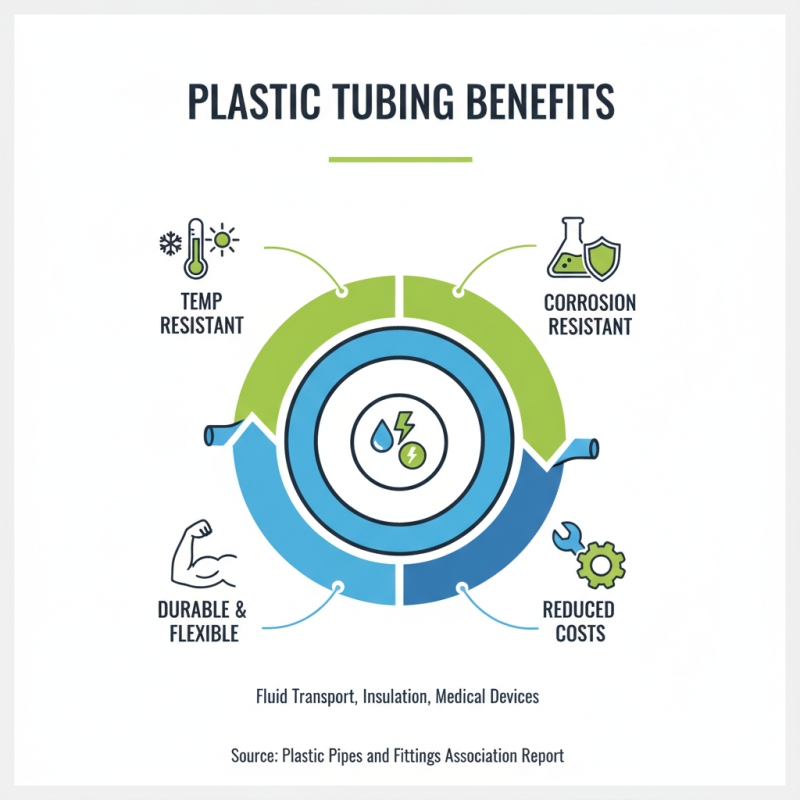

Plastic tubing has gained considerable popularity in various industries due to its inherent durability and flexibility. According to a recent report by the Plastic Pipes and Fittings Association, plastic tubing can withstand extreme temperature variations and is resistant to corrosion, making it an ideal choice for applications such as fluid transportation, electrical insulation, and medical devices. The material's resilience enables it to maintain structural integrity even in demanding environments, which leads to lower replacement costs and reduced downtime for projects.

Furthermore, the flexibility of plastic tubing allows for easy installation and adaptability to different configurations and spaces. A study from the Institute of Plastic Engineers highlighted that plastic tubing can be bent and twisted without compromising its strength, offering designers more freedom in developing innovative solutions. This capability not only simplifies the installation process but also enhances the overall efficiency of the project, as plastic tubing can navigate tight spaces and complex layouts with ease. As industries continue to embrace sustainable practices, the lightweight nature of plastic tubing reduces energy consumption during transport and installation, further solidifying its position as a vital component in modern engineering and construction projects.

Plastic tubing has become increasingly popular in various industries due to its remarkable cost-effectiveness compared to traditional materials like metal and rubber. According to a report by the Freedonia Group, the demand for plastic tubing is projected to grow at an annual rate of 5.6% through 2025, driven by its affordability and versatility. Plastic tubing typically costs 30-50% less than metal alternatives, making it a compelling option for budget-conscious projects. Furthermore, the lightweight nature of plastic reduces shipping and handling costs, providing additional savings across the supply chain.

When selecting materials for your project, keep in mind that plastic tubing is not only economical, but it also protects against corrosion, ensuring longevity over time. A study by the American Society for Testing and Materials highlights that plastic tubes can last up to 50 years in various applications, significantly outpacing the lifespan of metal options. This durability translates into lower maintenance and replacement costs, further enhancing plastic's value proposition.

Tips: When choosing plastic tubing, consider the specific requirements of your project—such as temperature tolerance and flexibility. Additionally, look for suppliers that offer bulk purchasing options, which can reduce overall costs. Lastly, always compare the performance characteristics of different materials to ensure that you select the best option for your needs, maximizing both efficiency and cost savings.

The use of plastic tubing in various industries has gained traction not only due to its versatility and lightweight nature but also because of its environmental considerations. With the global push towards sustainability, plastic tubing manufacturers are increasingly adopting eco-friendly practices. Data from *Plastics Recycling Update* indicates that the recycling rate for plastic tubing has improved significantly, with an estimated 36% of all polyethylene products being recycled in recent years. This demonstrates a growing recognition of the importance of circular economies where materials can be reused, thereby reducing waste.

Additionally, advances in bioplastics have opened up new avenues for environmentally conscious projects. According to a report published by *Smithers*, the market for bioplastics is expected to reach a value of $25 billion by 2025, illustrating a shift towards sustainable materials in manufacturing processes, including plastic tubing. These innovations not only reduce reliance on fossil fuels but also decrease carbon footprints, making plastic tubing an increasingly viable option for companies looking to improve their environmental impact. Such initiatives go hand-in-hand with meeting legislative requirements and consumer demand for greener products, which is becoming essential in today's market landscape.

| Benefit | Description | Environmental Consideration |

|---|---|---|

| Durability | Plastic tubing is resistant to corrosion and wear, making it a long-lasting option for various projects. | Long lifespan reduces the need for frequent replacements, contributing to lower waste generation. |

| Lightweight | Plastic tubing is significantly lighter than metal alternatives, allowing for easier handling and transportation. | Lower transportation energy costs and emissions due to reduced weight. |

| Cost-Effective | Generally, plastic tubing is less expensive than other materials, leading to savings on material costs. | Affordable options can encourage more sustainable choices in project designs. |

| Versatility | Available in various sizes and forms, suitable for different applications in various industries. | Adaptability can reduce the need for multiple materials, promoting resource efficiency. |

| Chemical Resistance | Plastic tubing can withstand a wide range of chemicals, making it ideal for industrial applications. | Prevents the leaching of harmful substances, supporting safer environment practices. |

Plastic tubing has become an essential component in a variety of industries due to its remarkable versatility and adaptability. One of the key sectors where plastic tubing shines is in the medical field. According to a report by the Technavio Market Research, the global medical tubing market is expected to grow at a CAGR of 8% from 2021 to 2025. This growth is largely driven by the increasing demand for biocompatible and flexible materials that can be tailored to specific medical applications. Plastic tubing is employed in various medical devices, from catheters to IV lines, offering both reliability and safety in critical environments.

In addition to the medical industry, plastic tubing excels in the manufacturing and construction sectors. Its lightweight nature and resistance to corrosion make it an ideal choice for conveying fluids, gases, or other materials. A study from MarketsandMarkets indicates that the global plastic pipe market is projected to reach $231 billion by 2025, with a significant portion attributed to the growing preference for non-metallic materials in construction. This trend highlights how plastic tubing not only meets the demands of modern engineering but also contributes to sustainability; for instance, its low weight allows for reduced greenhouse gas emissions during transportation and installation. These attributes underline the broad applicability of plastic tubing across diverse projects, proving it to be a superior choice for many industrial needs.