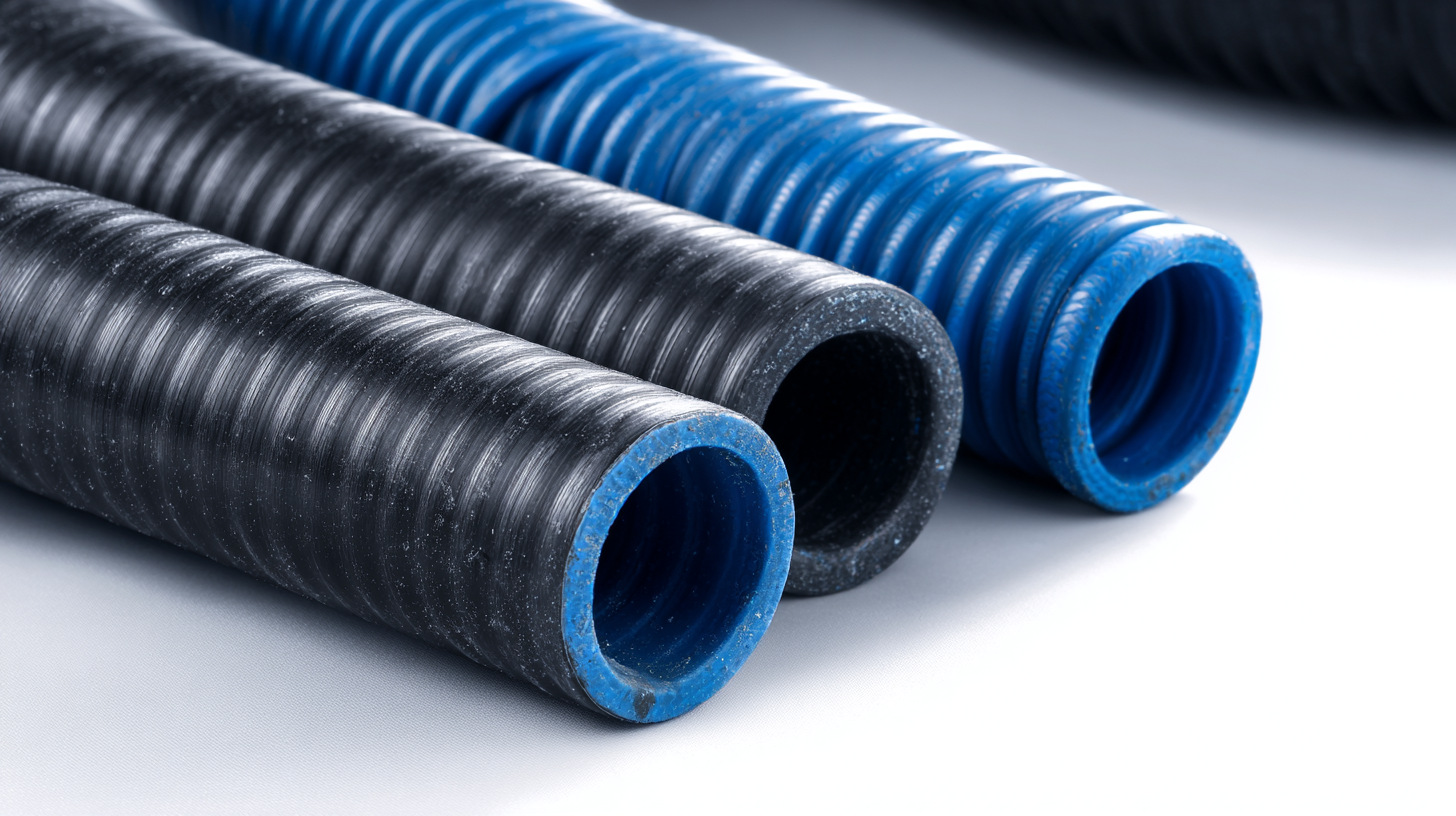

In the realm of industrial applications, the efficiency and effectiveness of material handling play a pivotal role in enhancing productivity and safety. The utilization of **2 suction hoses** has emerged as a significant advancement in this field, offering a range of operational benefits. According to a report by the Industrial Hose Association, the careful selection and configuration of suction hoses can lead to improved flow rates and reduced operational downtime, which can increase overall production capacity by up to 15%. This is particularly critical in sectors such as manufacturing and construction, where the demand for efficient material transport is paramount.

Moreover, employing **2 suction hoses** not only optimizes flow dynamics but also enhances the versatility of equipment. By effectively managing material transfer, industries can minimize risks associated with cross-contamination and streamline their processes. A study published in the Journal of Industrial Engineering highlighted that companies using dual hose systems reported a 20% decrease in material transfer times. Such improvements are instrumental in meeting stringent regulatory standards while maintaining high operational efficiency. Therefore, understanding the advantages and implementation strategies of **2 suction hoses** is essential for industrial operators aiming to enhance their operational workflows and competitive edge in today’s fast-paced market.

Using dual suction hoses in industrial applications brings numerous benefits that significantly enhance operational efficiency. One of the primary advantages is the increased flow rate achieved by having two hoses working simultaneously. This allows for faster material handling and minimizes downtime during processes that require liquid or particulate transfer. With dual suction capabilities, industries can handle larger volumes more effectively, ultimately leading to improved productivity.

Additionally, having two suction hoses enables flexibility in operations. For example, different types of materials can be conveyed at the same time without cross-contamination. This is particularly beneficial in environments where hygienic conditions are paramount, such as in food processing or pharmaceutical industries. Moreover, in the event of one hose becoming blocked or damaged, the other can continue to function, providing a safety net that enhances overall system reliability.

**Tips:** When implementing dual suction hoses, ensure both hoses are compatible with the materials being handled. Regular maintenance and inspections are crucial to prevent blockage and ensure optimal performance. Furthermore, while selecting hoses, consider varying diameters that could help create specific flow rates suitable for different applications to maximize efficiency.

In industrial settings, optimizing workflow is crucial for enhancing productivity and efficiency. The integration of two suction hoses in operations can significantly streamline processes by ensuring that materials are moved swiftly and with minimal interruption. By employing dual suction hoses, facilities can achieve a balanced flow of raw materials or waste products, allowing for simultaneous collection from multiple points. This not only reduces downtime but also minimizes the risk of bottlenecks that can occur when relying on a single hose system.

Moreover, utilizing two suction hoses can lead to improved safety and environmental considerations. With the ability to extract contaminants or hazardous materials from different areas at once, workers are less exposed to potential hazards. Additionally, this setup can facilitate better air quality within the workspace, as pollutants are efficiently removed from various locations. Overall, the use of two suction hoses not only enhances operational efficiency but also contributes to a safer work environment, making it an essential consideration for any industrial application aiming for optimal performance.

The choice between single and dual suction hose systems is crucial for optimizing performance in industrial applications. Single suction hoses can provide sufficient flow rates for many standard operations, but they often face limitations when handling high viscosity fluids or working in environments where the pressure drop must be minimized.

Implementing dual suction hoses in industrial operations can significantly enhance efficiency and productivity. By utilizing two suction hoses, companies can ensure a balanced flow of materials, reducing the risk of bottlenecks in the system. According to industry reports, operations that adopt dual suction systems can experience improved airflow by up to 30%, leading to faster processing times and more streamlined workflows.

When integrating dual suction hoses, it's essential to follow best practices to maximize their benefits. Regular maintenance and inspection of the hoses can prevent leaks and ensure optimal performance. Additionally, proper training for operators on how to effectively manage the dual system is crucial. For instance, conducting regular simulations can help staff become familiar with the setup, ultimately leading to reduced errors during operation.

Tips: Make sure to select hoses of identical diameter to maintain consistent pressure and flow. It's also advisable to monitor the performance metrics closely after implementation to assess improvements and troubleshoot any issues early. Regular feedback from team members can help in fine-tuning the system for further enhancements.

When selecting appropriate suction hose types for industrial applications, several key considerations must be addressed to ensure optimal performance and efficiency. Firstly, the material of the suction hose is critical. It should be selected based on the type of substances it will handle, such as chemicals, food products, or abrasive materials. For example, hoses made of PVC or polyurethane are suitable for lightweight applications, while rubber hoses are ideal for heavy-duty use.

Another important factor is the diameter of the suction hose. A larger diameter allows for greater flow rates, which is essential in high-demand scenarios. However, it is also necessary to consider the suction lift capability, as excessive length can lead to reduced performance. Additionally, flexibility and compatibility with existing systems are crucial. Hoses that are easy to maneuver can significantly enhance operational efficiency, especially in environments where space is constrained. By carefully considering these factors, industries can optimize their suction systems to meet ever-increasing demands while ensuring safety and reliability.

| Application Area | Advantages of Using 2 Suction Hoses | Considerations for Hose Selection | Material Type |

|---|---|---|---|

| Chemical Processing | Increased flow capacity and reduced risk of clogging | Chemical compatibility and temperature range | PVC, PTFE |

| Food and Beverage | Greater efficiency in transferring liquids, reducing processing time | FDA compliance and cleanability | Silicone, EPDM |

| Mining Operations | Improved suction power and reliability | Abrasion resistance and temperature tolerance | Rubber, Polyurethane |

| Construction Sites | Enhanced suction performance for heavy materials | Durability and flexibility under various conditions | PVC, Reinforced Rubber |

| Industrial Waste Management | Effective removal of waste and debris | Resistance to chemical attacks | HDPE, PVC |