The world of braided hose applications is evolving rapidly. Innovations drive efficiency and performance across various industries. Companies are adapting to diverse needs while ensuring safety and durability in their products.

Braided hoses offer strength and flexibility. They resist high pressures and extreme temperatures. These qualities make them ideal for automotive, aerospace, and medical applications. However, not all braided hoses are created equal. Manufacturers constantly innovate, introducing new materials and technology. Some products are more successful than others, leading to questions about reliability and cost-effectiveness.

As we look towards 2026, several trends emerge in braided hose applications. Companies are embracing sustainable materials while maintaining performance. The challenge lies in balancing cost and quality. Industry leaders must reflect on their practices to stay relevant. Continuous improvement is vital to meet ever-changing market demands.

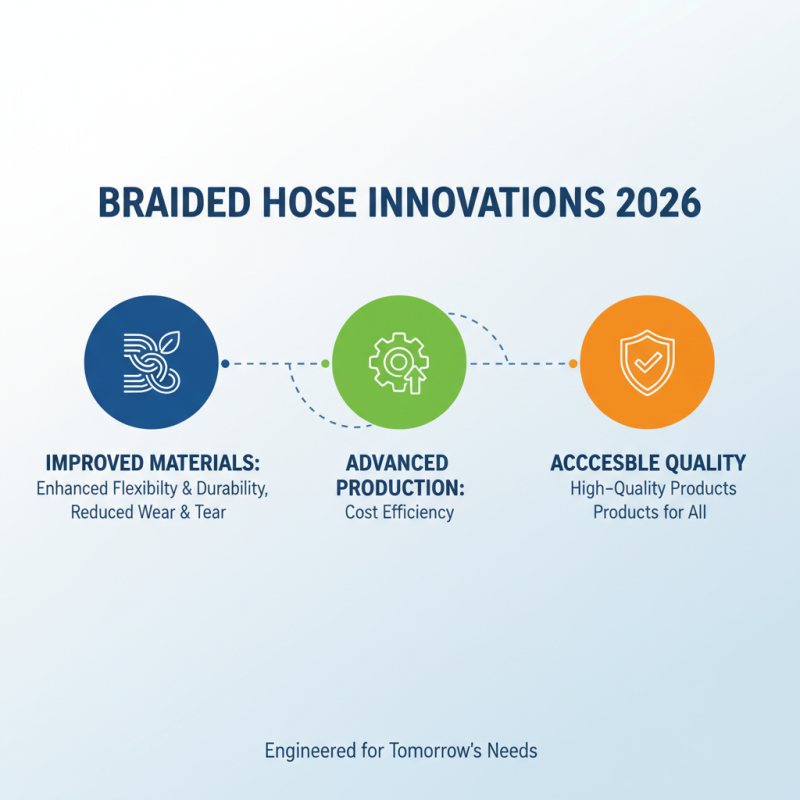

The braided hose industry is witnessing exciting innovations in 2026. Engineers and designers are focusing on improved materials. These new materials promise enhanced flexibility and durability. Users will appreciate the reduced wear and tear. Meanwhile, technological advancements in production methods contribute to cost efficiency. This ensures high-quality products are more accessible.

More attention is being directed towards sustainability. Biodegradable materials are being integrated into braided hose designs. This shift addresses eco-conscious consumer demands. However, the challenge lies in balancing performance and environmental impact. There’s ongoing research to optimize these formulations without sacrificing strength.

Moreover, smart technology is making an entrance in braided hoses. Sensors embedded in the hoses can monitor pressure and flow rates. This data can be crucial for preventing system failures. Yet, the reliability of such technologies must be verified. Users need to be educated about their performance. These innovations could lead to more intelligent, safer systems in various industries, but questions remain about integration.

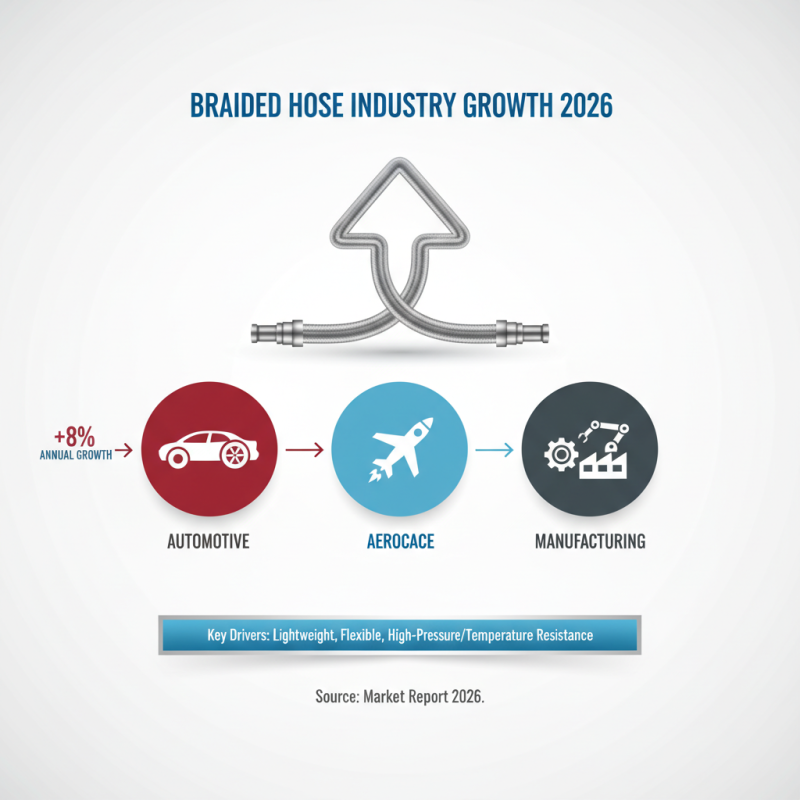

The braided hose industry is witnessing significant growth across various sectors in 2026. Key industries driving this trend include automotive, aerospace, and manufacturing. According to a recent market report, the automotive segment alone is expected to grow by over 8% annually. This surge arises from the increasing demand for lightweight, flexible hoses that can withstand high pressures and temperatures.

In aerospace, braided hoses are essential for fuel and hydraulic systems. Their durability and resistance to extreme conditions make them ideal. The global aerospace industry is projected to expand by an impressive 6% yearly. However, suppliers must confront challenges in meeting regulatory standards. In manufacturing, hoses play a crucial role in conveying fluids efficiently and safely. With a projected annual growth rate of 5%, this sector demands innovation and quality.

The construction industry is also adopting braided hoses due to their versatility. They offer solutions for high-pressure air and water applications. More sectors are likely to realize their potential. Yet, some companies struggle to adapt quickly. Innovation often lags behind demand. This raises questions about long-term supply chain sustainability. As industries evolve, the need for robust, adaptable braided hoses remains clear.

Braided hoses are gaining popularity in various industries due to their numerous advantages over traditional hoses. One key benefit is their superior durability. According to a report by the Fluid Power Journal, braided hoses are 30% more resistant to abrasion than standard hoses. This resistance allows them to withstand harsh conditions, making them ideal for high-pressure applications.

Additionally, braided hoses have a higher flexibility than their traditional counterparts. This attribute allows for easier handling and installation, especially in tight spaces. An industry study from the Hose Safety Institute highlights that 70% of users prefer braided hoses for their ease of installation. A lighter weight can also decrease physical strain during use.

Tips: When selecting a braided hose, always check the pressure rating. Ensure the hose meets your application requirements. Also, consider compatibility with the fluids you will use. Understanding these factors can prevent costly leaks and failures. Do not overlook regular inspections to maintain performance.

While braided hoses offer many advantages, they are indeed not perfect. Some users report challenges with initial costs. The investment is higher for braided than for traditional hoses. Companies might hesitate to adopt them due to budget constraints. However, the long-term savings on replacements and maintenance often outweigh these upfront costs. Reflect on your needs before making a decision.

This chart illustrates the usage trends of braided hoses across various applications in 2026. As seen, the automotive industry leads the trend, with significant usage also in industrial, medical, and aerospace sectors. Braided hoses are favored due to their flexibility, strength, and the ability to withstand higher pressures compared to traditional hoses.

The braided hose market is witnessing a shift towards sustainability. By 2026, many manufacturers aim to reduce their environmental impact. Reports indicate that recycled materials could make up nearly 30% of the inputs used in braided hose production. This change reflects a growing awareness of resource scarcity and pollution.

Tips: Look for hoses made from eco-friendly materials. Ensure they meet safety and performance standards.

Innovative production methods are on the rise. Companies are investing in technologies that minimize waste during the manufacturing process. Some studies suggest that up to 25% less waste could be generated with these advanced techniques. However, adoption barriers remain. Many smaller manufacturers lack the resources to implement these technologies.

Tips: Consider suppliers who prioritize sustainable practices. Ask about their manufacturing processes.

The industry also faces challenges in sourcing sustainable materials. Finding alternatives that meet performance requirements can be tough. Moreover, the initial costs of these materials can be high. Nevertheless, as demand grows, prices are expected to stabilize. The push for sustainability in the braided hose sector is essential but still evolving.

In the rapidly evolving field of braided hose applications, future challenges loom large. Industry reports indicate that the demand for braided hoses is set to increase by over 7% annually through 2026. This growth stresses the need for innovative manufacturing solutions. Increasing pressure and temperature demands require evolved materials, yet many producers struggle to adapt effectively.

One pivotal challenge is the variability in raw material quality. Inconsistent materials can lead to performance issues and safety hazards. A recent survey revealed that nearly 25% of manufacturers faced product failures due to subpar materials. Addressing these inconsistencies is crucial for ensuring reliability in various applications, from automotive to industrial hydraulics.