In an era where efficiency is paramount, the industrial sector is continuously seeking innovative solutions that can enhance productivity and streamline operations. Among these solutions, camlocks play a crucial role in facilitating quick and secure connections in fluid transfer applications. According to the latest report by the International Association of Fluid Connectors, the adoption of camlocks has increased by over 30% in the past three years, underscoring their growing importance in various industries, including oil and gas, agriculture, and manufacturing.

Industry expert Dr. Emily Harper, a leading authority in fluid connection systems, once stated, "The evolution of camlocks technology has revolutionized the way industries manage fluid transfer, enabling faster operations and reducing downtime." As we look toward 2025, five key innovations in camlocks are set to further enhance operational efficiency. These advancements promise to not only improve safety standards but also contribute to sustainable practices by minimizing spills and wastage.

As industries navigate the challenges of a rapidly changing landscape, understanding these innovations is critical. In this article, we will explore the top five camlocks innovations that are driving efficiency in the industry, providing insights into how these technologies will shape the future of fluid management systems.

The advancements in camlock technology are primarily driven by the introduction of revolutionary materials that significantly enhance both durability and performance. One of the key innovations is the use of high-performance polymers, which are designed to withstand extreme temperature fluctuations and corrosive environments. These materials not only extend the lifespan of camlocks but also reduce the overall weight, leading to easier handling and installation in various industrial applications.

In addition to polymers, the integration of advanced composites offers superior strength and resistance to physical wear and tear. These composite materials are engineered to resist impacts and abrasion, making them ideal for heavy-duty applications in sectors such as manufacturing and transportation. The combination of lightweight properties with enhanced strength ensures that camlocks can operate reliably under demanding conditions, thereby improving operational efficiency. This focus on material innovation is setting a new standard for camlock performance and durability in the industry.

This chart illustrates the performance enhancements of camlocks driven by innovative materials in 2025. The data reflects the improvements in durability and efficiency across five different material innovations.

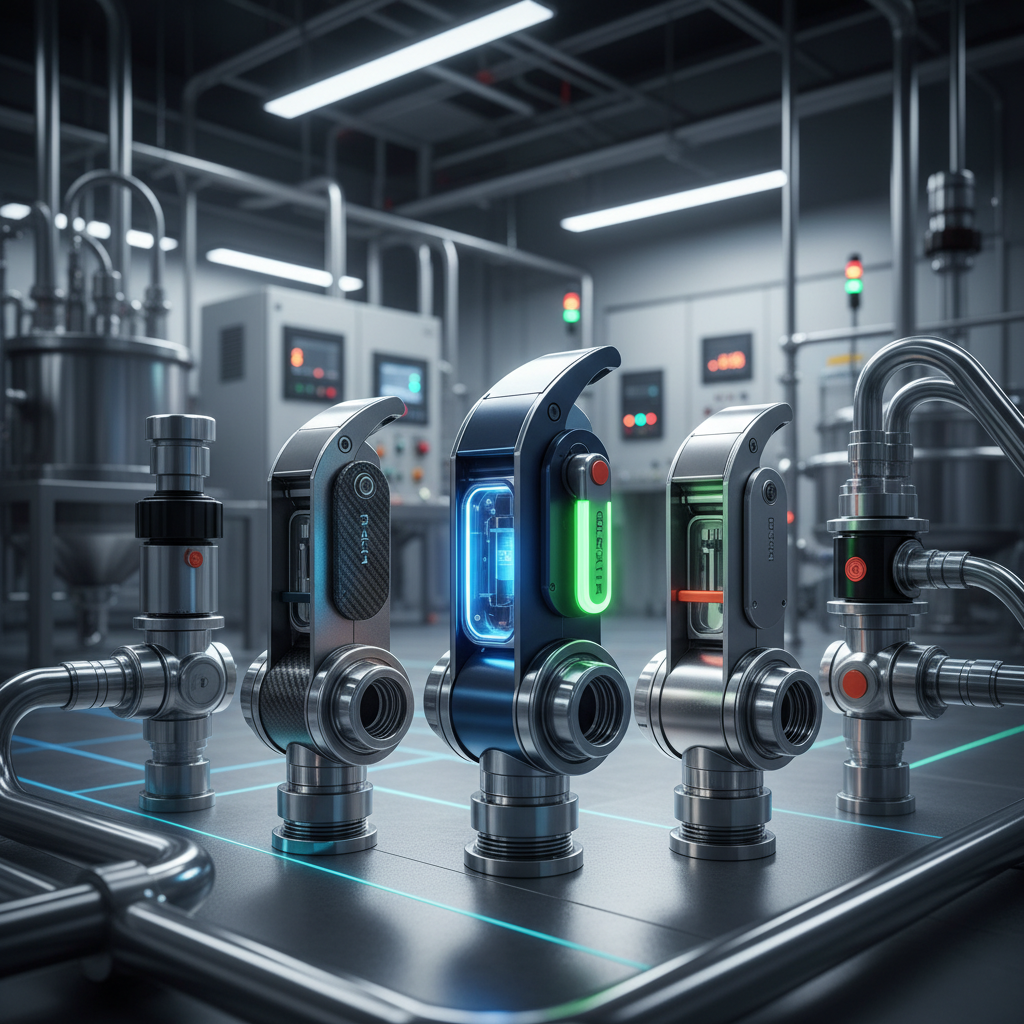

As industries strive for greater efficiency, the integration of smart technology into camlock systems is revolutionizing how operations are monitored and controlled. Real-time monitoring capabilities allow operators to track the performance and status of camlocks instantly, leading to more proactive maintenance and reduced downtime. By utilizing advanced sensors and IoT platforms, businesses can gather crucial data that aids in decision-making and optimization.

Tip: Consider implementing a centralized monitoring system that consolidates data from all camlocks. This not only provides a comprehensive view of system performance but also helps in identifying patterns that could lead to better resource allocation and efficiency improvements.

Moreover, the integration of AI-driven analytics transforms conventional camlock systems by predicting potential issues before they arise. With predictive maintenance, companies can optimize their operational workflows, reducing unnecessary costs associated with unexpected failures. This shift not only enhances safety but also supports a sustainable approach to resource management.

Tip: Regularly update your monitoring software to leverage the latest features and improvements in AI analytics. This ensures you maintain a competitive edge and maximize the effectiveness of your camlock systems in driving industrial efficiency.

In the rapidly evolving landscape of industrial applications, the focus on ergonomic design in camlocks has become paramount. By prioritizing user experience and safety, manufacturers are innovating to create camlocks that not only streamline operations but also reduce the risk of workplace injuries. Advanced materials and thoughtful engineering are being employed to ensure that camlocks are not only robust but also lightweight and easier to handle, significantly reducing user fatigue during prolonged use.

Moreover, the integration of ergonomic features such as contoured grips and intuitive locking mechanisms has enhanced usability. These improvements allow operators to complete tasks with greater ease and precision, minimizing the potential for mishaps. The emphasis on safety is evident in designs that include features like automatic locking and visual indicators that confirm secure connections, ensuring users are always aware of the camlock status. This attention to detail reflects a broader trend in industrial design, where user-centric innovation is increasingly critical in driving efficiency and improving overall workplace safety.

In recent years, sustainability has become a pivotal focus in the manufacturing sector, especially regarding camlock innovations. With industries striving for environmentally friendly practices, the use of waste materials for manufacturing processes is gaining traction. For instance, innovative research is exploring the potential of using shredded plastic bottles and high-density polyethylene as alternative materials in camlock production. This shift not only helps reduce plastic waste but also enhances the efficiency of manufacturing operations.

Market trends indicate a significant growth trajectory in sustainable industries. Reports suggest that the green electronics manufacturing market is projected to expand from $16.81 billion in 2024 to $46.53 billion by 2029, reflecting a compound annual growth rate (CAGR) of 22.5%. This trend is mirrored in the stock clamshell packaging sector, expected to reach USD 9.2 billion by 2032, driven by sustainability initiatives. Such data underscores the urgent need for industries, including camlock manufacturing, to innovate sustainably and embrace practices that contribute to a greener future while maintaining operational efficiency.

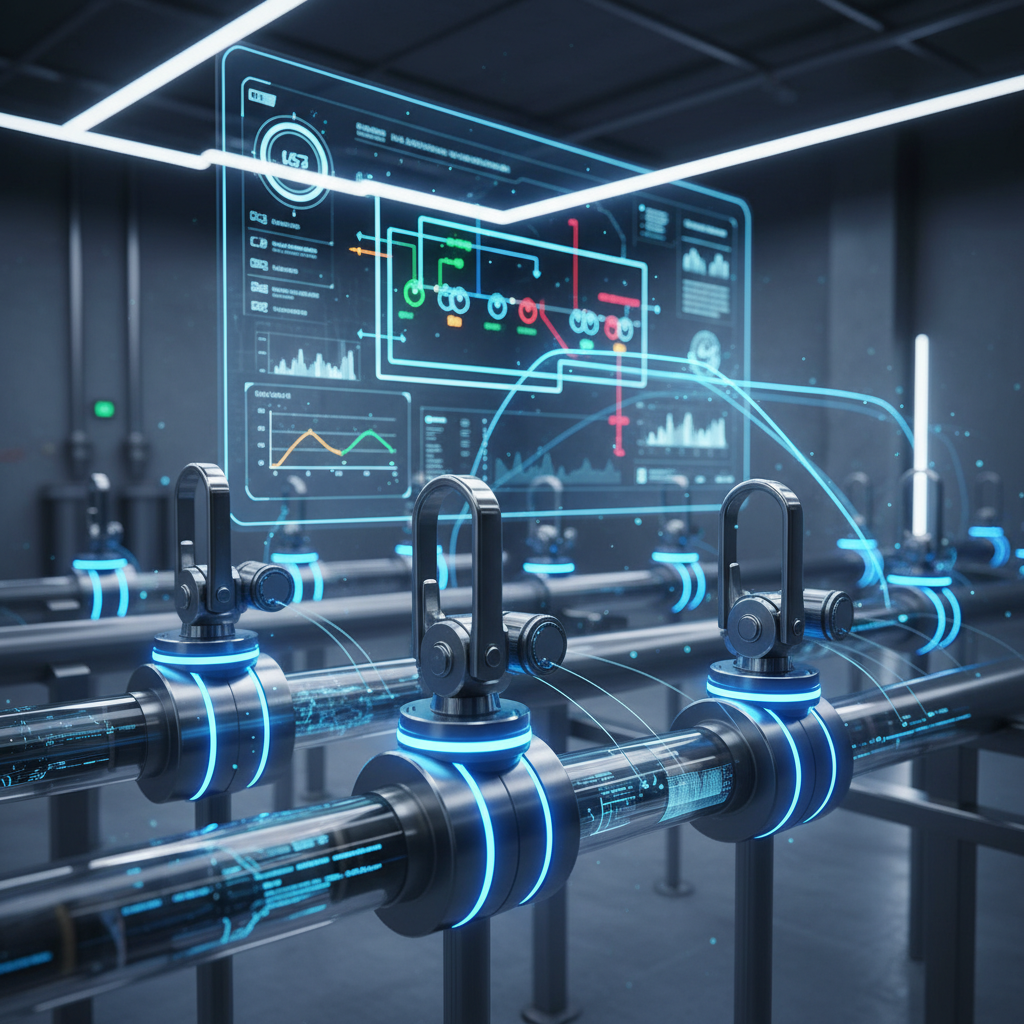

The rise of automated assembly solutions is revolutionizing the way industries operate, focusing on increased efficiency and cost reduction. These innovations are designed to streamline production processes, significantly reducing the time and labor required for assembly tasks. By integrating advanced robotics and smart technology, companies can achieve higher precision and consistency in their production lines. This not only enhances the quality of the products but also allows for a quicker turnaround time, ultimately leading to improved customer satisfaction.

Furthermore, the implementation of automated assembly solutions minimizes human error and mitigates workplace injuries, contributing to a safer work environment. These systems often include real-time monitoring and analytics, enabling manufacturers to identify bottlenecks and optimize their workflows dynamically. As businesses seek to remain competitive in a rapidly evolving market, adopting these innovations becomes essential for driving operational excellence and achieving substantial cost savings in the long run.